In the current conjuncture, where sustainability has become a strategic pillar for industrial operations, energy efficiency stands out as a crucial element. This relevance is partly due to its proven ability to significantly reduce operating costs - in some cases up to 40% of the production budget. The integration of ESG Practices (Environmental, Social, and Governance) further emphasizes the need for sustainable and efficient approaches.

Asset Monitoring and Management: a prerequisite

To achieve operational and energetic efficiency, continuous equipment monitoring is essential. This involves the adoption of predictive maintenance techniques centered on reliability, using technologies such as sensors and analysis to anticipate failures before they occur. These practices not only minimize maintenance costs, but also ensure that equipment works optimally, consuming less energy.

The OEE (Overall Equipment Effectiveness) (OEE) indicator evaluates the availability, performance and quality of equipment, becoming fundamental to measure energy efficiency and maintenance effectiveness. Well -maintained equipment is less likely to failures that can lead to unplanned stops, resulting in lower energy consumption and reducing operating costs.

Bridgemeter: The IIOT Solution for Energy Efficiency

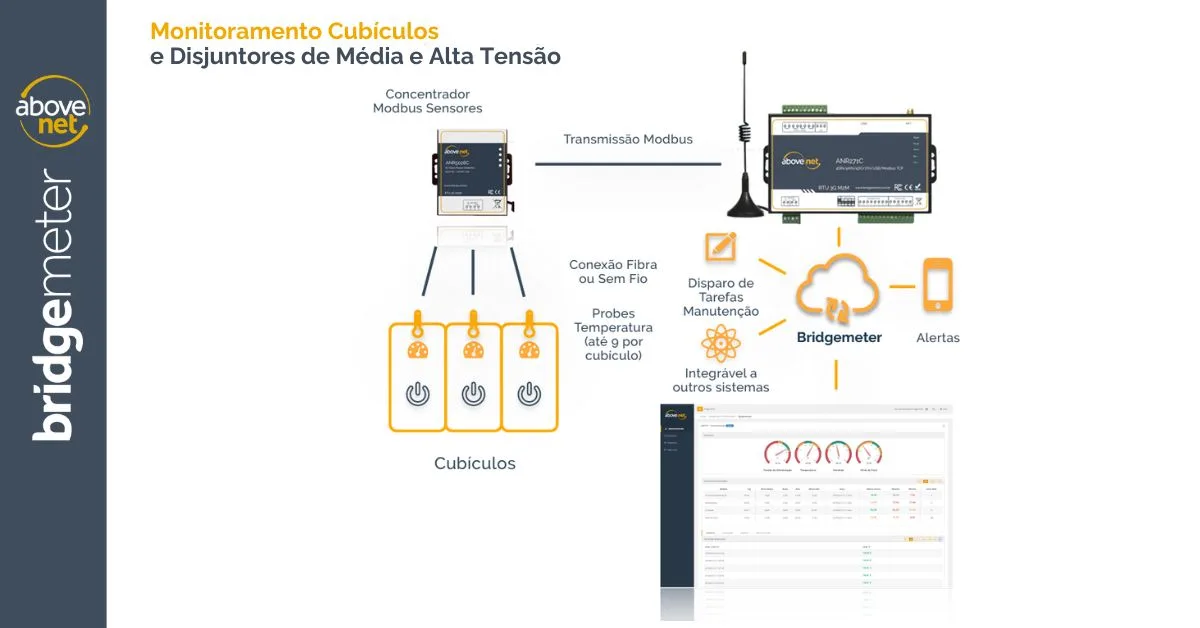

Especially designed for critical applications, Bridgemeter enables intelligent remote monitoring, ensuring greater operational safety and return on immediate investment. Through full dashboards, you can view information in real time, including predictive analysis, alarms and notifications.

To illustrate, electrical panel failure management exemplifies Bridgemeter's impact on energy efficiency, allowing proactive actions to maintain operational efficiency and reduce energy consumption.

Power bus temperature control

The temperature control of the energy bus temperature emerges as a critical aspect for the effectiveness of the energy system within industrial facilities. Operations with energy buses at high temperatures are indicative of energy losses that not only affect efficiency, but also increase the risk of operational failures. The adoption of real -time temperature monitoring systems is therefore fundamental to ensure early interventions in energy inefficiency scenarios, such as inappropriate electrical connections or overload situations.

Through the implementation of these technologies, it is possible not only to prevent overheating failures, but also to promote a safer and more efficient operation of the energy buses. This practice ensures the maintenance of operational temperature within ideal limits, contributing significantly to the optimization of energy consumption and the safety of facilities.

Flexible architecture and interoperability

Bridgemeter's flexibility, compatible with a variety of sensors and systems, enhances energy efficiency. With its flexible architecture, it offers a composed Hardware and Software solution that adapts to any type of sensor, PLC and industrial equipment. Compatibility with SCADA/ERP systems and the ability to integrate predictive analyzes reinforce its position as an essential tool for measuring points interoperability.

SAAS marketing model

The Bridgemeter SaaS model eliminates the need for equipment purchases or system licenses, facilitating the adoption of this technology. Support for a wide range of sensors and devices, Bridgemeter offers flexibility and ease of implementation, reinforcing its value as a key energy efficiency solution for the industry.

Conclusion

Amid the operational and energetic challenges faced by the modern industry, Bridgemeter presents itself as an indispensable tool. Supporting the transition to more sustainable and efficient practices, this IIOT solution not only promotes more effective energy management, but also aligns industrial operations with sustainability and corporate governance, outlining the future of energy efficiency in industry.

Application

Ensure energy efficiency and prevent fires with monitoring of electrical and command panels

The electrical and command panel monitoring catalog shows how Bridgemeter, an industrial IoT solution for Predictive Above-Net , allows intelligent remote monitoring of any quantity of electrical panels and real-time command.

Also read:

What is Data Center Infrastructure Management (DCIM)?

Revolutionizing the maintenance of cold chambers, refrigerators and refrigerators