Data intelligence to reduce losses and maximize operational efficiency.

The energy transition has been repositioning the green hydrogen as a key component of global decarbonization strategies. Alongside renewable sources, it emerges as a promising alternative to replace fossil fuels and enable a large-scale low-carbon economy. However, its adoption at an industrial pace requires more than just technical feasibility: it requires ensuring efficiency, stability, and operational reliability, especially in highly complex environments with high infrastructure costs. This is precisely where the experience of Above-Net makes a difference. Working for years with remote monitoring solutions In diverse sectors, such as sanitation, the company has consolidated a technological model focused on the intelligent management of critical assets, capable of detecting anomalies in real time, anticipating failures, and reducing costly corrective interventions. This expertise, built in environments operating under constant pressure, can be applied to the demands of the green hydrogen sector.Parallels between sanitation and green hydrogen

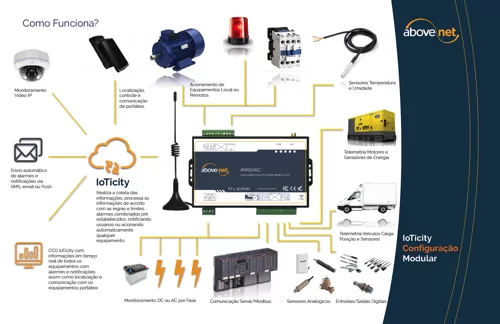

There's a clear parallel between the two realities. In sanitation systems, for example, the operation of pumps, valves, filters, and pumping stations depends on operational continuity and predictability. Any failure compromises service delivery and wastes energy, resources, and time. In a green hydrogen plant, the rationale is the same: electrolyzers, compressors, refrigeration systems, and storage units must operate in a coordinated manner, with no room for error. When operational risk is high and the equipment has high added value, intelligence applied to operations ceases to be an advantage and becomes a requirement. Above-Net offers solutions capable of transforming this scenario, with architecture-based monitoring systems. edge-cloud, fault-tolerant connectivity and integration capabilities with sensors, PLCs and systems Scady, the company offers a robust approach to capturing, interpreting, and responding to operational data in real time. This allows managers to have precise visibility into each point of the network and act preventively, in a planned, and strategic manner. More than reducing maintenance costs, this embedded intelligence increases operational reliability, increases asset availability, and strengthens the safety of environments where outages represent direct losses in energy efficiency and return on investment. In the case of green hydrogen, where competitiveness is directly linked to plant performance, every percentage point of operational gain counts.Above-Net as a partner in the energy transition

With a consolidated track record, Above-Net positions itself as a technology partner for companies operating in critical and distributed networks. By transferring practical knowledge to a new energy vector, the company reaffirms its commitment to innovation and the transition to a more sustainable, digital, and resilient energy model. Ultimately, what Above-Net delivers is much more than connectivity or automation: it is the ability to make technical decisions based on reliable data, at the right time, and with a real impact on operations.Know details of Bridgemeter IoT