Remote Monitoring for Equipment Manufacturers

Maximize efficiency with Remote Monitoring for Equipment Manufacturers: advanced IoT solutions for real-time control and maintenance.

Challenge

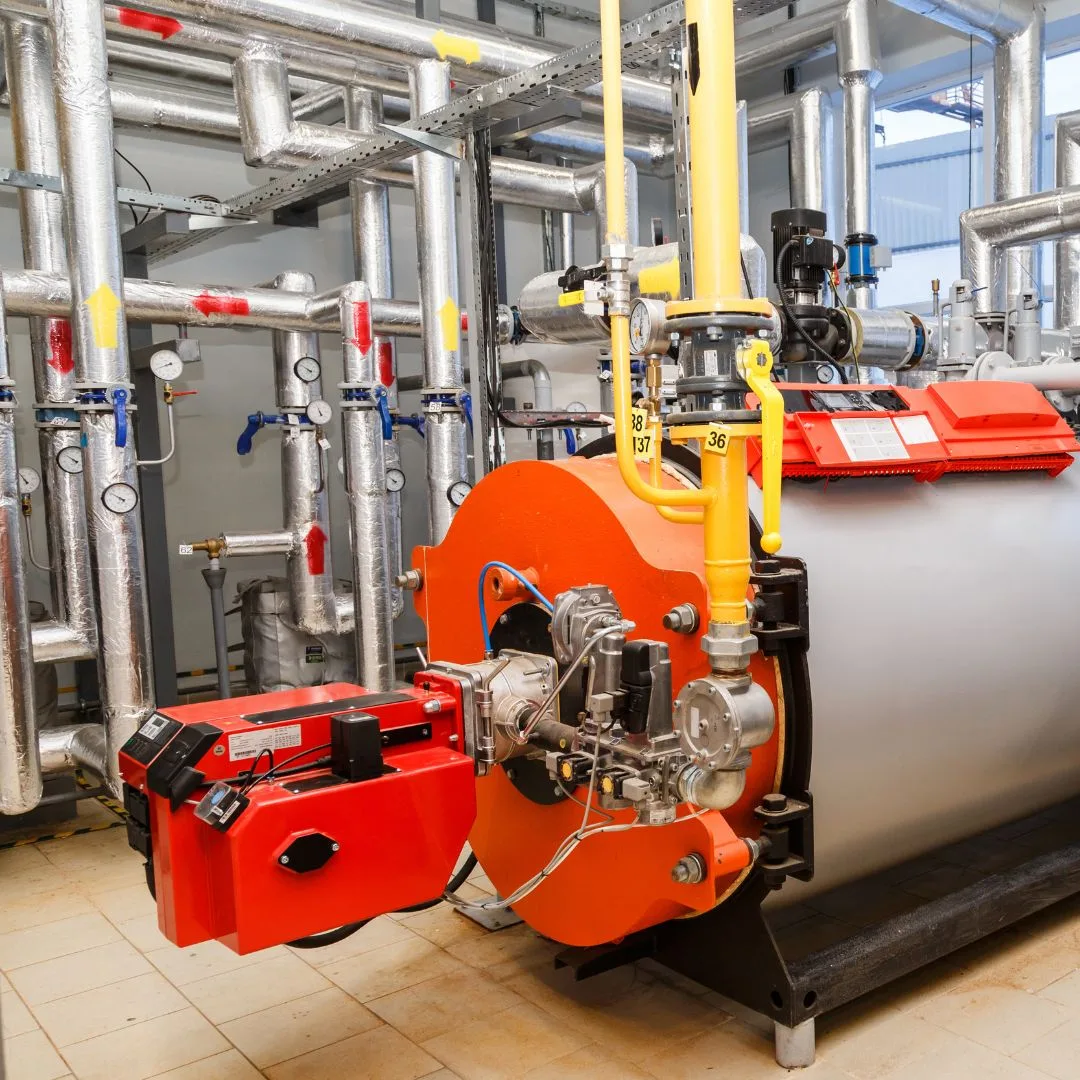

Identify and anticipate operational problems with equipment located at the manufacturer's customers to reduce downtime and maintenance costs.

Solution

The equipment manufacturer acquired the Bridgemeter remote monitoring solution as a White Label model and offers the service to its customers from the factory to anticipate problems and reduce travel costs under current maintenance contracts.

The Client is a multinational manufacturer of industrial equipment and provides technical assistance and maintenance services for its machines to its customers. His biggest difficulty was identifying a problem with a machine remotely in order to identify faults and appropriate maintenance procedures. Furthermore, the entire predictive maintenance process was carried out on site, connected to the machine via a maintenance team computer.

This model, in addition to being inefficient, generated extremely high shipping costs and staff to the manufacturer who depended on physical visits for a simple inspection of the machine's operation.

The project was developed based on Above-Net Bridgemeter Industrial IoT monitoring . Through the platform, the customer can monitor in real time the operation of all equipment under maintenance contracts around the world.

Within various scalability and security requirements, communication with the equipment controllers (PLCs – Siemens with S7Comm communication) was necessary, which Bridgemeter is compatible and approved for communication with.

Another important requirement was the flexibility of communication in different countries, independent of the local network of the manufacturer's customers, avoiding limitations in communication and resistance in installation by IT teams. The communication technology chosen was via cellular data using Above-Net .

All equipment parameters are transmitted through a cellular gateway offered in the solution, processed and stored in real time. Bridgemeter 's functional layer acts instantly, automatically triggering alarms and notifications based on intelligent rules defined by the platform user.

Furthermore, the Bridgemeter indicates to the local maintenance team the trend or existing problem, as well as the Checklist of tasks to be carried out to solve it.

With in-depth experience in developing remote industrial communication solutions, Above-Net offered a Turn-Key IoT solution that covers the integration, communication, information, functionalities and business layers in just one product, saving the customer time and resources and providing the true digitization process of the process.