The industry currently has high operational complexity that makes it difficult to increase efficiency. Most of manufacture technology has not advanced at the same pace as consumer and business systems. And the reduction in labor cost is no longer a differential factor. Therefore, it is necessary and fundamental, the improvement of existing performance and business model and greater agility in the monitoring of emerging technologies.

New market demands, regulations, competition and others create a challenging and uncertain scenario. This way, companies need flexibility and ease to remain competitive.

Traditional management systems responsible for management and monitoring do not have an architecture that allows changes quickly and dynamically or much less that can anticipate and notify fault events predictively and proactively.

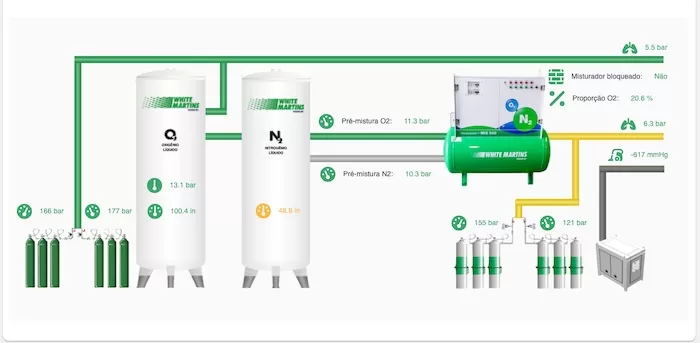

Another important aspect is connectivity with a variety of equipment. To achieve operational efficiency, all readings of any subsystem in the same application must be converged providing a global view of the operation.

The latter brings therefore the connectivity with various types of protocols. A IIOT solution cannot be limited to a select number of protocols, much less to the most commonly used protocol groups today. It is necessary to connect legacy equipment and systems, ensuring interoperability and convergence for the same platform with the past, present and the future.

When Above-Net began the development of Bridgemeter in 2014, it realized this desire and market application and built a modular solid architecture in layers that allows the total interoperability of equipment.

In addition to connectivity options and transmission media (mobile, Lora, NB-IOT, WiFi…), today the platform offers over 140 types of protocols that allow us to apply the plug and play concept of any equipment or sensor, even legacies. With such flexibility, it is possible to undergo a gradual process of digital transformation with costs adjusted to the customer's investment reality.

From the collection of information, all data is stored in a structured manner allowing the interconnection with several other market tools horizontally for specific data analysis.

Another difficulty identified by Above-Net in 2014 was the ability to anticipate failures and communication to the user of events in such extensive equipment parks. The current control center model is impractical and inefficient as it disperses attention to events that in 90% of the time work correctly. The challenge is not to lose or fail to transmit critical information as soon as possible to the team in charge of a change in any reading whatever the size of the monitored infrastructure.

Bridgemeter uses modern real -time notifications techniques that guarantee the delivery of information proactively. That is, even if the operator is in a breakfast break or that his control center panel no longer includes equipment, the system automatically identifies and notifies everyone involved with an action plan.

In fact, Bridgemeter customers perceive a substantial economy of service time compared to the same process before using the solution. In such cases, maintenance teams can act even before call center call or perception by the installed control center. An economy in the operation, in time and direct increase in customer satisfaction.

This notification process is fired with an automated task manager that controls the evolution step by step until the situation is normalized. The team has a repository of online documents integrated with the system for manual consultations, plants, certifications, images or any other document that is important for the verification and completion of the task. Another economy with practicality, centralization of information and increased efficiency in the execution of maintenance services.

Another important point in product design was the understanding that Bridgemeter is not a competitor of the SCADA systems but a component that adds flexibility and intelligence to remote monitoring. Bridgemeter can act uniquely or in conjunction with the already installed scada. In the second option it also solves several connection problems encountered on the market, including the need for multiple PLP connections or multiple SCADA systems. Once again, allied flexibility and intelligence for increased efficiency.

As an example, using Bridgemeter Above-Net integrates various equipment and stations of a large sanitation company, allowing remote control and telemetry, as well as reliable communication with the customer's SCADA system. Above-Net was the only one capable of crossing fragility barriers and standardization deficiency in local communication, delivering a reliable, high availability and excellent cost-effective solution.

Above-Net also understood from the beginning that a IIOT platform is just one of the components of a digital transformation process and for that it would need to interview with other systems ensuring the continuity of information to complete the process in a 100% digital way. Therefore, Bridgemeter has a series of communication options ERP and Management Systems either by APIs or other forms of integration.

Another important factor has always been usability. Traditional monitoring systems have several menu, complicated operation and learning curve that requires constant training and specialized programming team. In the medium and long term, it becomes unsustainable as it is an activity outside the business focus of the company that does not have programming personnel or ventures into a solution on its own. Result, the change process is extremely bureaucratic and expensive.

Bridgemeter's intuitive interface offers a configuration of supervision diagrams, alarms and intelligent rules in a instantaneous manner according to the User's authority allowing immediate update on the trigger and decision -making actions. More flexibility and agility to increase efficiency.

Finally, Bridgemeter also contributes to minimizing investments as it is offered in flexible packages such as SaaS (solution as a service) at no cost of development or acquisition of licenses and can include all connectivity equipment, updates and maintenance.

Are you interested in an intelligent IIiot solution for your business? Contact us today by filling out the form below: