WWTPs with membrane bioreactor technology require continuous monitoring of their operating parameters. Bridgemeter has enabled a significant increase in production and efficiency.

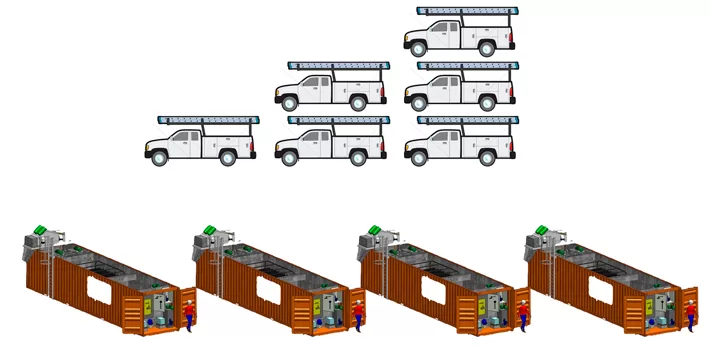

DECENTRALIZED OPERATING MODEL

- MBR treatment plants require constant management due to the nature of the membrane fouling process.

- Decentralized operation with significant distances

- Requirement for 1 operator per operating station

- Supervision and engineering vehicle for every 3 stations

- On-time data collection from the engineering team

- Difficulty viewing the operation

- Inconsistency in production level

- Constant unscheduled stops

- Production reports for SLA

Solution: Industrial IIOT

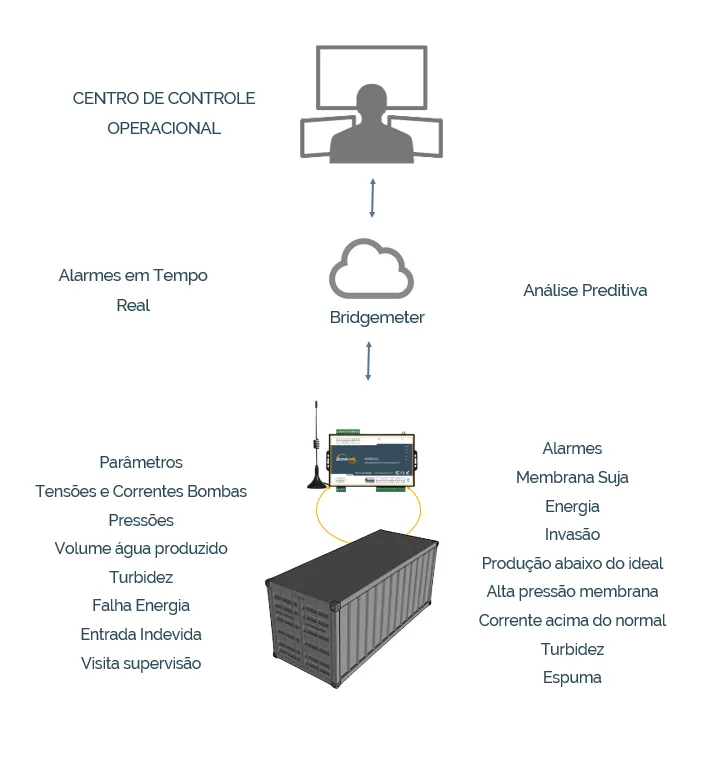

ALL OPERATION IS MONITORED IN REAL TIME

The monitoring system records and sends notifications to responsible operators for appropriate action and cycle corrections. The water meter measurement report reflects the reduction or increase in daily treated water productivity.

Using information from the manufacturer, intelligent cross-conditions were created so that the system could interpolate the intersection of several parameters, replacing sensors that were not available on the market. For example, when pump current and transmembrane pressure (TMP) measurements are crossed, the system learns and alerts for ranges corresponding to: Clean Membrane, Partially Fouled Membrane, and Fouled Membrane. The maximum allowable pressure is also constantly monitored.

All PLC parameters are also monitored.

Results

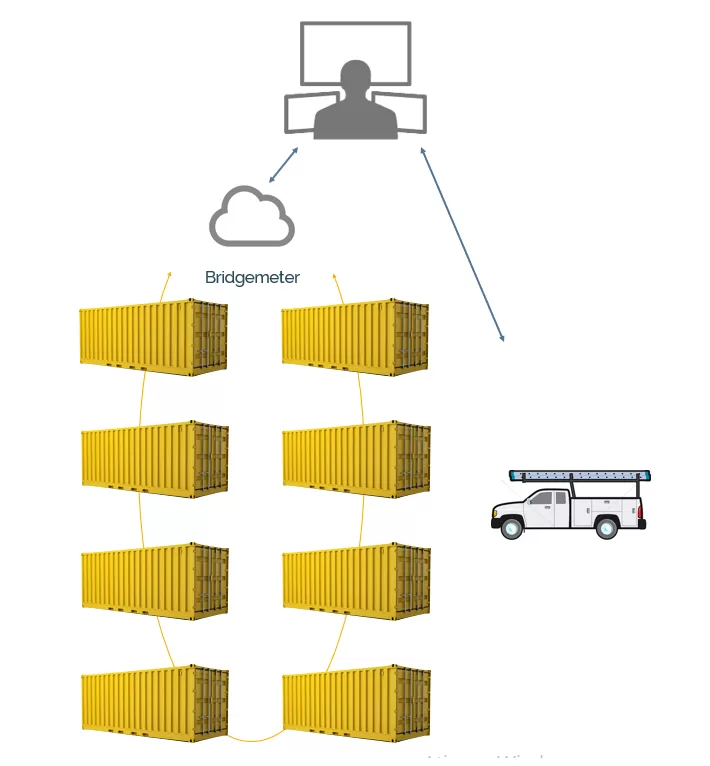

ALL OPERATION IS MONITORED IN REAL TIME

- Average 30% increase in production

- 27% reduction in unscheduled downtime

- Permanence of TMP pressure in 95% of measurements

- Daily record of ETE production after using the system

- Reduction of staff and operational infrastructure by 40%

- Automatic production and SLA reporting

- Monitoring presence of supervision team.

Monitoring provided unprecedented insight into the wastewater treatment plant, as previously, only a "snapshot" of operator visits was available. With the Industrial IoT system, it was possible to create a "film" with live transmission of readings taken during the treatment process and intelligent alarms and notifications. Particularly in industry, even minimal increases in productivity can generate significant improvements in results with very low implementation costs, as in this case study.

Interested in Industrial Telemetry and IoT Solutions?