Attention to the issue of vaccines , amid the Covid-19 pandemic, highlighted an area of great importance in healthcare establishments: the Cold Chain . This is a part of the hospital operation that uses equipment such as refrigerated chambers, freezers and air conditioners to maintain adequate temperatures, avoiding changes that could compromise the quality of medicines and vaccines . Such changes could result in discard, depriving people of being immunized or medicated.

Power generators , in the same way, are critical equipment to safeguard the process, as they make up for any supply failures, ensuring permanent operation. Thus, telemetry and monitoring constitute essential technological resources to maintain security.

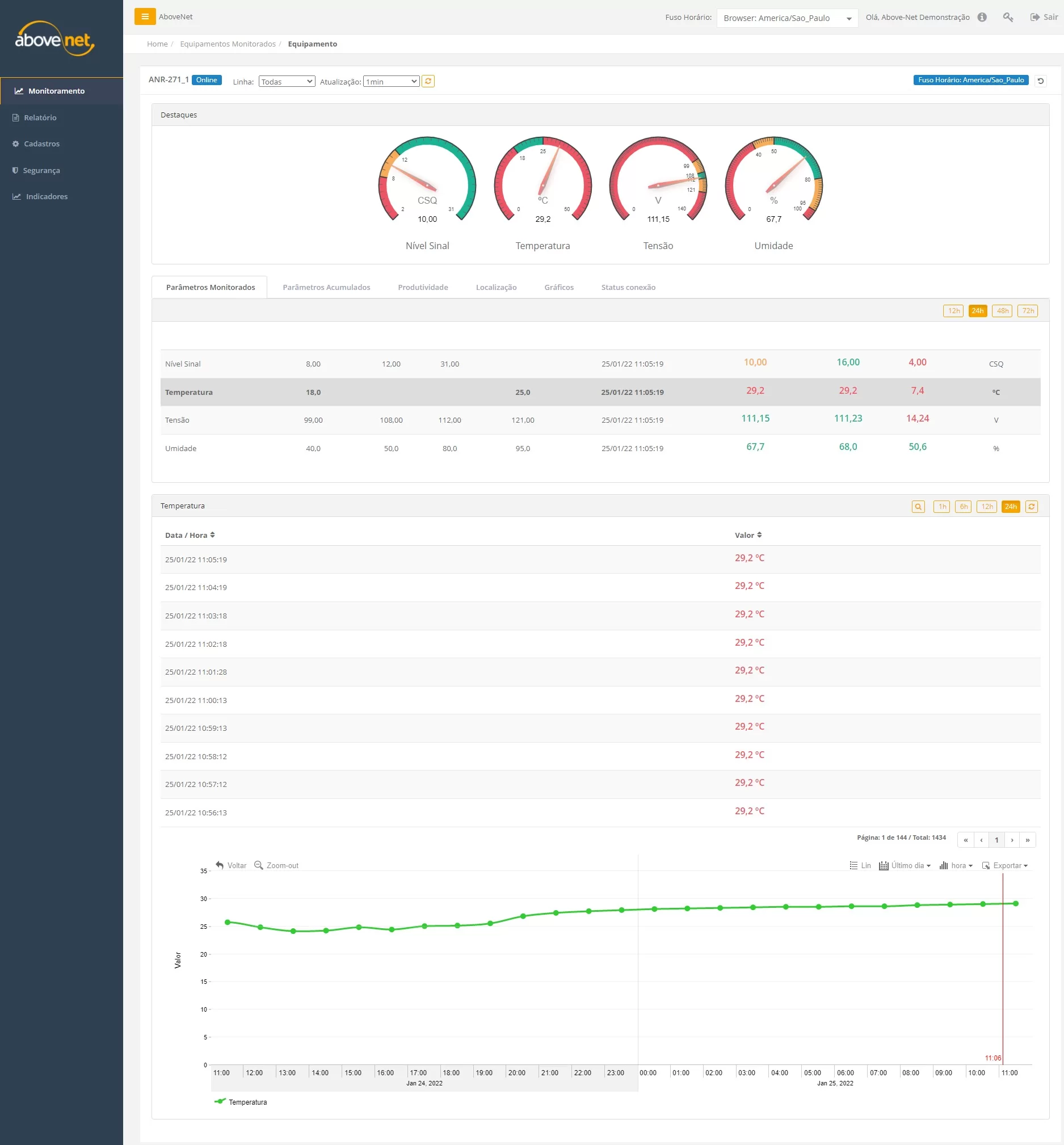

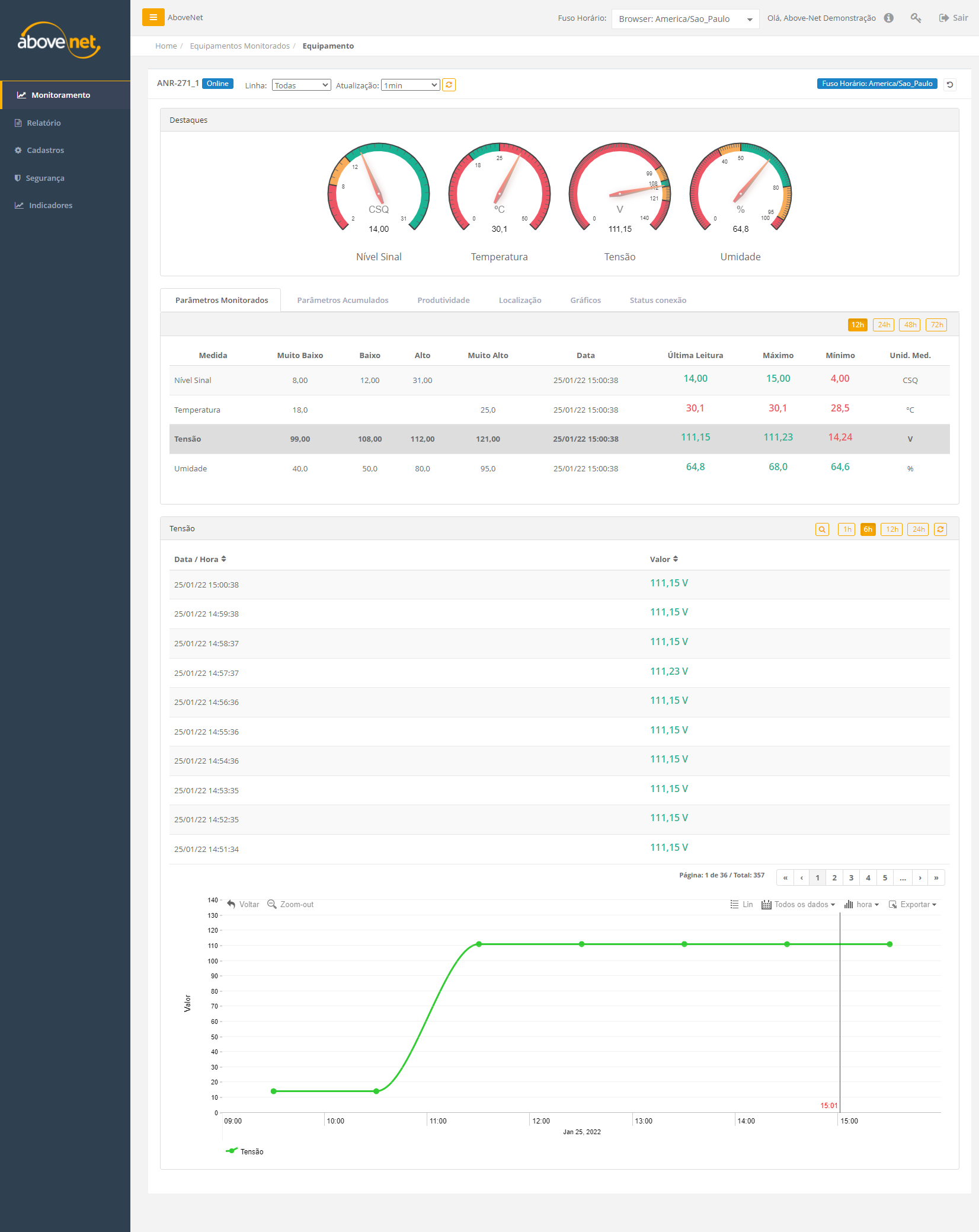

Bridgemeter Above-Net 's IIoT solution , has the Cold Chain module that allows monitoring of temperature Bridgemeter humidity , voltage and current of equipment typical of this operation. The system monitors relevant variables and allows the creation of alarms and customizable rules , helping the responsible team to keep the Chain operating within the best market practices and generating reports and graphs that provide support for quality assurance.

Similarly, Bridgemeter allows generators to be monitored. Data such as output voltage, current, temperature, fuel level, among others, also with configurable alarms and reports, ensure that the equipment will be available when needed.

Bridgemeter – Cold Chain was developed to allow the responsible teams to manage all parameters involved in the perfect operation of the system Bridgemeter With this, it is possible equipment failures through the analysis of trend curves , enabling Predictive Maintenance.

The solution is modular and allows deployment as needed, streamlining the process and optimizing resources , and can be deployed to monitor a unit or a network of hospitals with access profiles in compliance with the LGPD . The technology eliminates the need to monitor dashboards, as notifications of variations are sent via App directly to the responsible maintenance team.

The system also functions as a record and audit of the Cold Chain operation, in order to generate systemic evidence of the entire process' compliance with health standards.

Are you interested in telemetry and industrial IOT solutions?