Overload and heating: discover how Bridgemeter monitors and prevents electrical failures in real time, preventing structural fires in critical periods.

Brazil is facing a worrying increase in cases of structural fires, as revealed by the recent survey by the Instituto Sprinkler Brasil (ISB) . August 2024 recorded a new record of 234 occurrences, surpassing all previous months of the year and second only to August 2021 in the historical series. This significant increase coincides with the intensification of heat waves that are plaguing several regions of the country, a phenomenon worsened by El Niño and which, according to experts, is likely to persist in the coming years.

ISB consultant, Marcelo Lima, highlights the seriousness of the situation: “This data reveals an increase in fire records in Brazil. The daily news monitoring carried out by the ISB remains the only way to estimate the state of fires in Brazil, since statistics on incidents collected by state fire departments are not disclosed”.

The Impact of Climate Change on Structural Fires

The record heat waves observed in several regions of Brazil are not isolated events, but part of a global warming trend. The El Niño phenomenon, in particular, has intensified these effects, leading to extreme temperatures that test electrical systems and building infrastructures.

In this extreme heat scenario, the risks of structural fires increase significantly. Overloaded electrical equipment, refrigeration systems working at their limit and construction materials subjected to high temperatures create an environment conducive to the start and rapid spread of fires. The situation is even more critical in densely populated urban areas, where a fire can quickly spread to neighboring structures.

Limitations of Traditional Fire Prevention and Fighting Solutions

Faced with this scenario, organizations follow Brazilian standards that guide the installation of fire fighting systems such as extinguishers, sprinklers, hydrants and others. Although these measures are important, they only act after the start of the fire, not preventing its occurrence. Sprinklers, for example, are effective in containing flames, but they do not prevent damage caused by fire and smoke, in addition to the use of water in the fight, which in most cases causes more damage than the fire itself.

Furthermore, preventive techniques such as manual thermography of electrical infrastructure, although useful, have significant limitations:

- Insufficient temporal coverage : Manual thermography, performed annually or periodically, covers less than 1% of the equipment's operational time, leaving 99% of the period subject to unmonitored risks.

- Exposure to risks : This approach exposes technicians to unnecessary dangers during inspections.

- Dependence on human skill : Effectiveness largely depends on the skill of the operator and the quality of the equipment used.

- Deterioration of thermal windows : The accuracy of readings can be compromised by the degradation of thermal windows over time.

- Specific load conditions : For accurate readings, equipment must be operating under specific load conditions, which is not always possible during scheduled inspections.

These factors combined make manual thermography an unreliable method for the ongoing and effective prevention of structural fires.

Bridgemeter : The Revolution in Predictive Monitoring of Electrical Panels

It is in this challenging context that Bridgemeter emerges as the definitive solution for preventing structural fires. This innovative real-time predictive monitoring system for electrical panels represents a technological leap in the protection of critical infrastructures.

Operation and Main Features

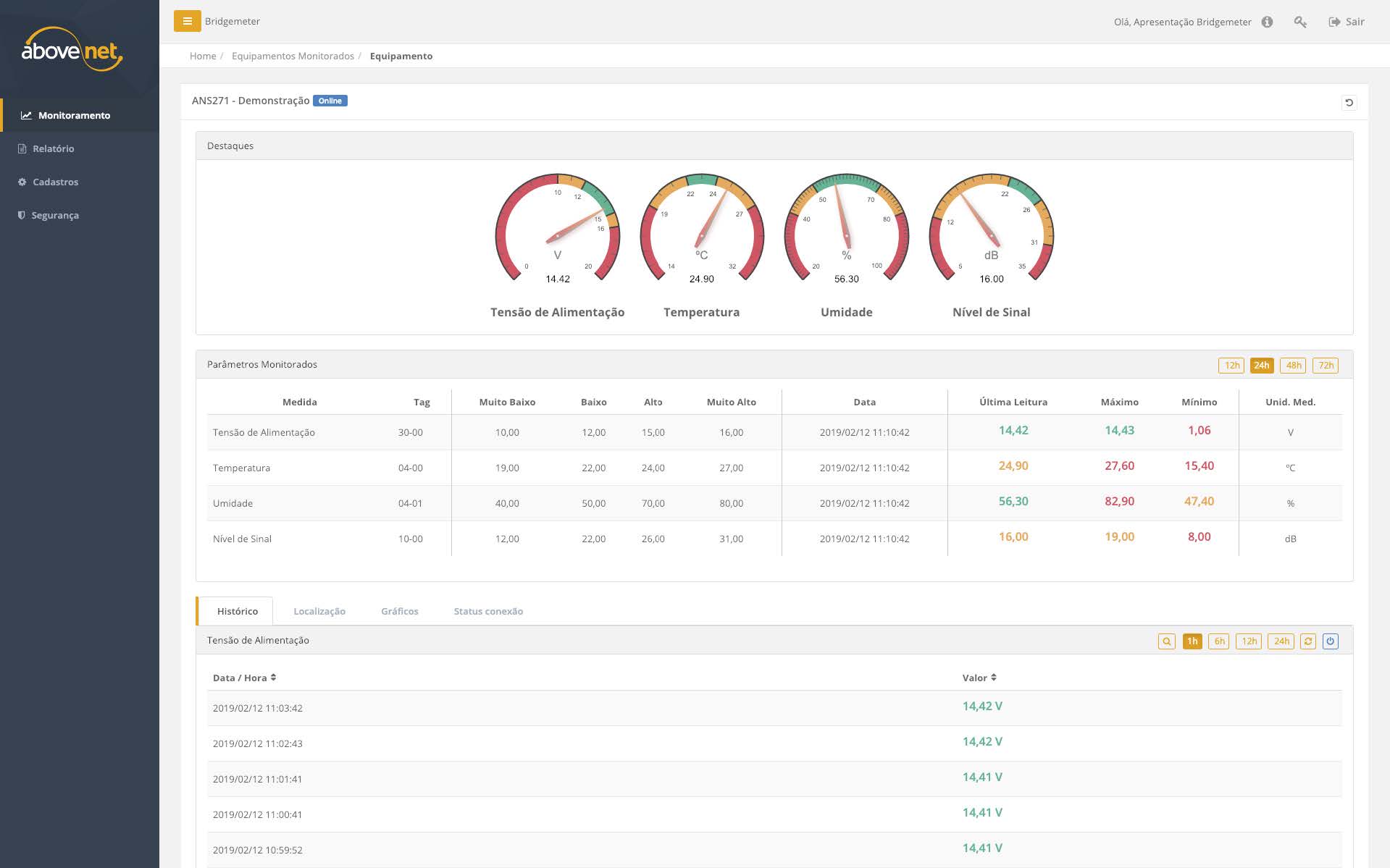

Bridgemeter uses advanced sensors to continuously monitor crucial parameters such as voltage, current, power and, most importantly, temperature of electrical panels. Unlike periodic inspections, Bridgemeter provides 24/7 surveillance, identifying anomalies and concerning trends long before they become critical issues.

Main features of the system:

- Continuous monitoring : Uninterrupted surveillance, covering 100% of operational time.

- High-precision sensors : Capture accurate data on temperature, current and other vital parameters.

- Real-time predictive analytics : Uses advanced algorithms to predict potential failures before they occur.

- Intuitive interface : Detailed dashboards accessible via computer, tablet or smartphone.

- Automatic notifications : Immediate alerts sent to responsible staff when abnormal conditions are detected.

- Integration with other systems : Ability to connect with existing management systems for a holistic approach to security.

- Affordable Installation : Offered as a solution as a service model, its installation becomes financially viable.

Advantages over Traditional Methods

Bridgemeter overcomes the limitations of traditional methods in several aspects:

- Proactive prevention : Identifies potential problems before they become critical, enabling preventive actions.

- Improved safety : Reduces the need for frequent manual inspections, minimizing technicians' exposure to risk.

- Constant accuracy : Not affected by factors such as thermal window degradation or specific load conditions.

- Resource savings : Optimizes maintenance processes, reducing operating costs and extending the useful life of equipment.

- Historical data and trend analysis : Provides valuable insights for continuous improvements in electrical infrastructure.

Practical Applications of Bridgemeter in Fire Prevention

Bridgemeter can be deployed in a wide range of environments, each with its specific challenges:

Commercial and Residential Buildings

In office buildings and residential condominiums, Bridgemeter constantly monitors the main and secondary electrical panels. This is particularly crucial during periods of high demand, such as during heat waves when air conditioning usage increases dramatically. The system can detect incipient overloads and alert management before critical failures occur or fires start.

Industrial Facilities

In industrial environments, where energy demand is high and constant, Bridgemeter plays a vital role. It monitors not only the main panels, but also specific high-consumption equipment. This allows for more efficient energy management and prevents unscheduled shutdowns that could result in large financial losses.

Hospitals and Healthcare Facilities

In hospitals, where continuity of power supply is literally a matter of life and death, Bridgemeter provides an additional layer of security. It monitors not only main panels but also backup systems, ensuring that critical equipment never loses power due to unforeseen electrical failures.

Data Centers

For data centers where precise temperature control is crucial, Bridgemeter not only monitors electrical panels but can also be integrated into cooling systems. This ensures a stable operating environment and prevents failures that could lead to catastrophic data loss.

The Future of Fire Prevention with Bridgemeter

In a scenario where climate change is intensifying the risk of structural fires, Bridgemeter presents itself as an indispensable tool. Its implementation is not just a security measure, but a strategic investment that protects lives, assets and business continuity.

As cities become smarter and more connected, systems like Bridgemeter will be increasingly integrated into urban infrastructure. This will enable a more holistic and efficient approach to fire prevention and large-scale emergency management.

Conclusion

While traditional solutions like sprinklers and manual thermal inspections have their place, Bridgemeter represents the future of structural fire prevention. By adopting this advanced technology, organizations not only protect themselves against the growing risks associated with heat waves and electrical overload, but also position themselves at the forefront of intelligent and sustainable management of critical infrastructures.

In a world where prevention is increasingly crucial, Bridgemeter offers not only security but also peace of mind. It is a solution that looks to the future, preparing buildings and infrastructures for the climate and technological challenges that lie ahead. With Bridgemeter , we are not only addressing today's problems, but anticipating and preventing tomorrow's challenges.

Learn more about real-time predictive monitoring of electrical panels by downloading the catalog below.

Application

Ensure energy efficiency and prevent fires with Monitoring of Electrical and Control Panels

The Electrical and Control Panel Monitoring catalog shows how Bridgemeter , Above-Net 's Industrial IoT solution for predictive analysis, allows intelligent remote monitoring of any size of electrical and control panels in real time.