In recent years, technology has been a great ally for hospitals and clinics, bringing innovations that optimize the work of healthcare professionals and improve the quality of patient care. In particular, one of the main technological changes that has revolutionized the hospital environment is the Internet of Things (IoT).

IoT is a technology that connects physical devices to the internet, allowing the exchange of information and remote control of these objects. In the hospital context, the IoMT (Internet of Medical Things) can be applied in several ways, from real-time monitoring of patients to the management of equipment and stocks of medicines and materials.

Process automation is an increasingly evident need in hospitals and clinics. With IoMT, it is possible to reduce the time spent on manual and repetitive tasks, allowing healthcare professionals to dedicate more time to caring for patients. Furthermore, IoMT can contribute to reducing human errors and errors, increasing patient safety and improving the efficiency of hospital processes.

According to a report from Research and Markets , the global IoMT market in healthcare is expected to grow from US$127.7 billion in 2023 to US$289.2 billion in 2028. This means that more hospitals, clinics and healthcare professionals healthcare will be using IoT devices to improve their medical services and treatments.

IoMT Applications in Hospital Infrastructure

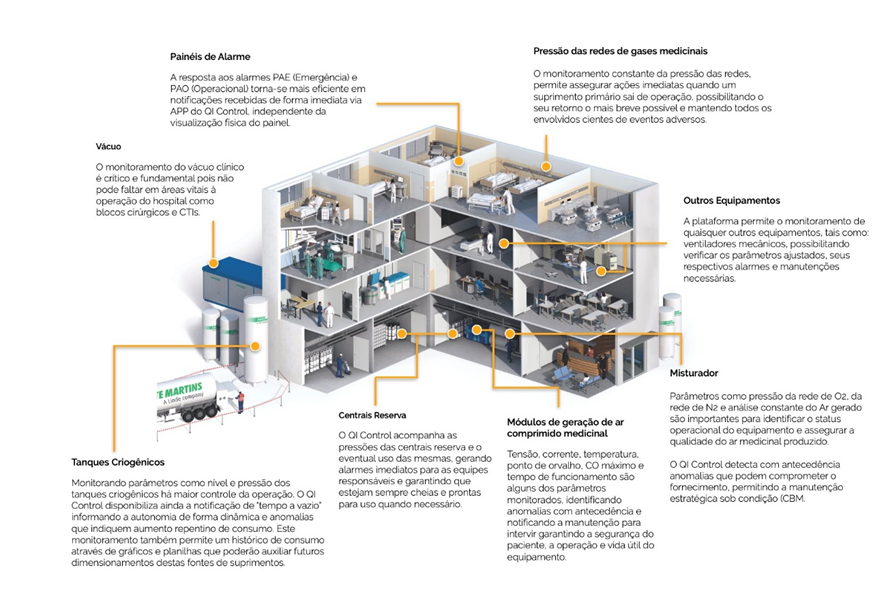

Gas Networks: Through sensors installed at consumption points, in generation center controllers or in the network itself, it is possible to collect real-time data on flow, pressure, voltages and currents, temperatures, number of activations, start of operation or any other information for analyzing operation. These are sent to the cloud platform, where they are analyzed in real time and stored for notification and visualization on dashboards and APPs respectively. Thus, the operation receives advance notifications of operational degradation while managers can monitor performance, identify possible failures or leaks and optimize the use of resources. Among the monitored systems we can mention:

- Cryogenic Tanks,

- Reservation Centers,

- Medical Compressed Air Generation Modules,

- Medical Air Mixers,

- Vacuum Modules Alarm Panels (PAE) and (PAO)

Magnetic Resonance Equipment

The solution monitors equipment such as compressors and chillers that are part of the MRI infrastructure. Continuous monitoring of the infrastructure allows the detection of anomalies, issuing automatic notifications via APP to the maintenance team before the failure becomes irreversible, thus enabling the continuity of services.

By monitoring parameters such as voltage, current, humidity, water temperature and pressure, it is possible to guarantee the best operating condition of various equipment vital to the operation of resonance and imaging.

The system also has complete control dashboards with real-time readings, as well as history, predictive analysis, alarms and triggered notifications, providing increased operational safety and reduced maintenance costs.

The Cold Chain

Cold chain monitoring in hospitals is crucial to ensure the effectiveness and integrity of temperature-sensitive products, such as medicines, vaccines and biological samples, which are stored and transported at controlled temperatures. Inadequate temperatures can compromise the quality of products and, consequently, put patients' health at risk.

This process is complex as it involves temperature control at all stages, from storage to distribution of products. It is necessary that the temperature is maintained within a specific range, which varies according to the type of product, to ensure that it maintains its properties and effectiveness.

IoMT technology can significantly contribute to this task. Using sensors, it is possible to monitor the temperature in real time and receive alerts in case of variations. Furthermore, it is possible to store data in the cloud and have access to detailed reports on the product's temperature history.

This technology allows for greater precision and efficiency in monitoring the cold chain, reducing the risk of product loss and ensuring patient safety. Furthermore, the use of sensors can help identify problems more quickly, allowing immediate action to correct the failure.

Another advantage of using IoMT technology in cold chain monitoring is cost reduction. With an automated monitoring system, it is possible to reduce the need for in-person inspections, in addition to avoiding losses due to temperature increases.

Boiler Monitoring

The boiler is responsible for supplying the steam used in various processes within the hospital, such as sterilizing equipment and surgical materials. In addition, the boiler is also responsible for heating water for bathrooms and other activities.

Failure to operate the boiler can lead to serious consequences, such as accidents with burns and even explosions. Therefore, constant monitoring is essential to identify possible problems before they become critical.

In this sense, IoMT has a fundamental role to play. With installed sensors, it is possible to monitor several parameters in real time, such as temperature, steam in the network and water pressure.

This data is sent to an analysis platform, which uses algorithms to identify possible problems and alert those responsible for maintaining the equipment. In addition, the platform can also generate reports with information about boiler performance over time, allowing hospital managers to make data-based decisions about preventive or condition maintenance (CBM) or equipment replacement.

Monitoring Primary Hospital Cabins

The importance of monitoring the primary cabin of hospitals is unquestionable. With IoMT, it is possible to monitor different aspects, such as temperature, humidity, voltage, current, for example. The variation of any monitored parameter is identified and through alarms, maintenance teams are informed to act immediately, allowing activities to continue.

Remote Patient Monitoring

IoMT can remotely monitor patients, allowing vital data to be collected and transmitted to medical staff in real time. This allows for continuous monitoring of patient health, management of chronic diseases and early detection of complications.

QI Control – Intelligent Management and Monitoring of Hospital Infrastructure

In an exclusive partnership with White Martins, Above-Net launched QI Control , an intelligent IoT monitoring solution for hospital infrastructure.

QI Control enables intelligent management of hospital infrastructure, providing information on the operational conditions of centers and networks, correlating measurements and generating real-time alarms of adverse situations, such as failures or possible wear and tear in a hospital operation.

Control and Notifications via APP

The QI Control APP is practical and easy to use. On the main screen, there are active or recent alarms from all monitored locations in the hospital network.

When clicking on the alarm or equipment, all alarms and parameters listed in order of limit criticality are displayed. This way, the technician has immediate access to information that could impact the operation in the short term.

In addition to quantitative parameter information, the application has a real-time view of supervision diagrams, trend graphs and a documentation repository for maintenance monitoring.

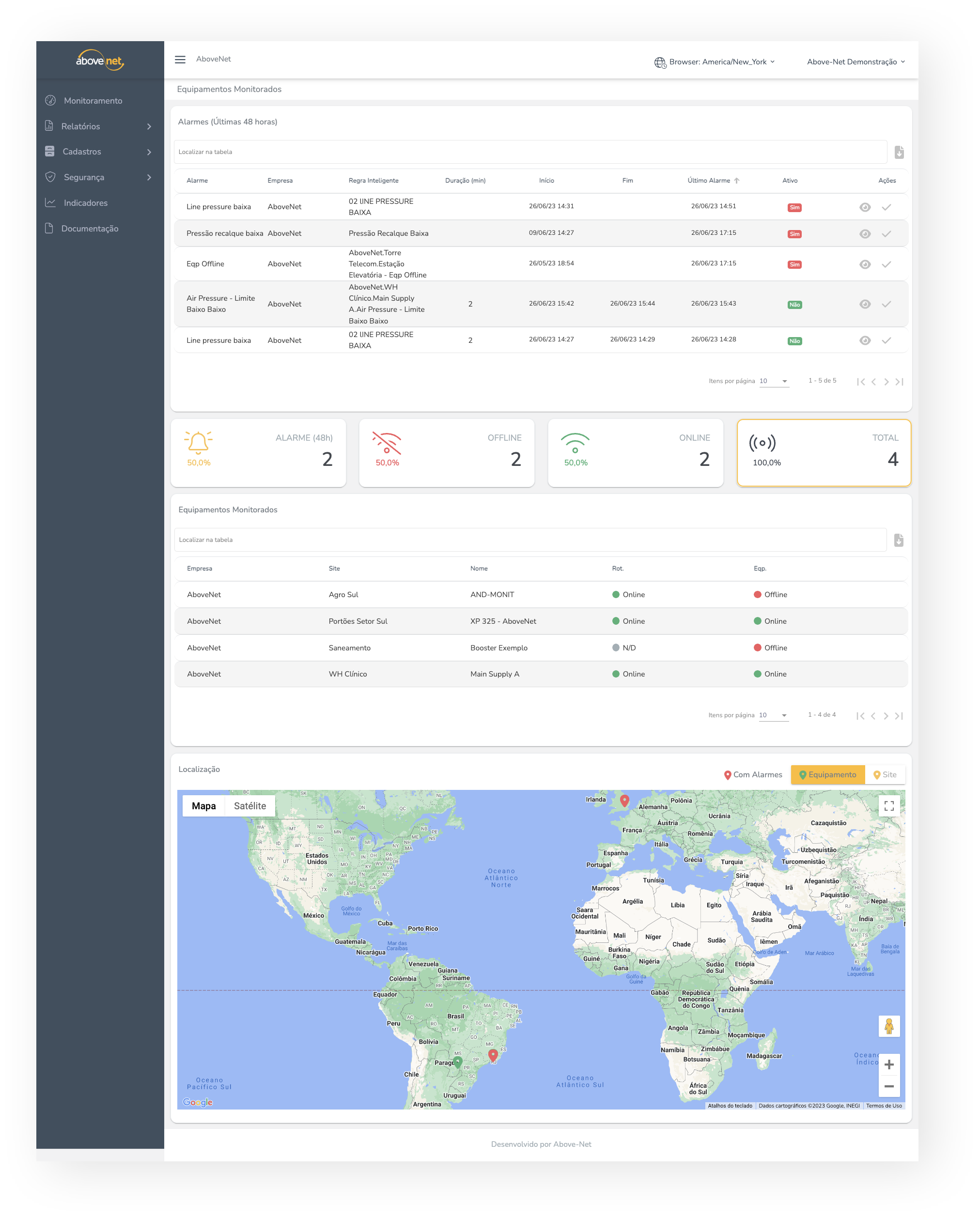

Control via WEB

QI Control offers dashboards for controlling and monitoring the entire hospital infrastructure.

Through an intuitive and simple to use interface, the system offers real-time intelligent alarm panels listed by priority on a main page. In another option, you can search for the network hospital or monitored equipment through a Google-style search or by location on the map.

When detailing any equipment, the system is capable of monitoring simple, accumulated parameters and also providing customized function calculations with their respective alarms and notifications.

In the graphics section, you can cross-reference historical information on any system parameter, export it to different formats and even generate instant reports.

Are you interested in an Industrial IoT Smart Monitoring Solution? Fill in the form below, we will contact you: