The increase in hospital fires in Brazil indicates a growing concern with safety in one of the most critical environments for humanity. According to the Sprinkler Brazil Institute in 2023, 49 cases of fires were recorded, a 16.9% jump in occurrences compared to the previous year.

The data signal an urgent need for review and strengthening of hospital fire protection measures. These incidents not only interrupt vital health services, but also pose an extreme risk for patients and professionals.

Recent occurrences illustrate the gravity and human impact of these claims. In one case, the emergency evacuation of an intensive care unit led to the tragic death of an elderly patient , highlighting the vulnerability of individuals who depend on these health services. In another episode, a short circuit in air conditioning equipment caused intense smoke emission in a hospital, generating panic and requiring an immediate response from emergency teams to avoid further damage.

These events reinforce the importance of establishing and maintaining effective methods and hospital fire prevention measures. The difficulty of manual inspection, ignorance of the state of critical parameters indicating an ignition and the potential of human error in equipment maintenance, highlight the urgency of adopting intelligent mechanisms and technologies for proactively rapid reactions.

Risk mitigation by identifying critical points and contour systems

Prevention of proactive hospital fires begins with the identification and mitigation of risk before they become a real threat. In the event of a fire it is necessary to have sure that contour systems come into action as projected.

Hospital kitchens

The most common place of starting hospital fire in the world, and in Brazil is no different, is the kitchen. These environments are considered high risk zones, and especially in hospitals, due to the restriction of patient mobility, the nature of equipment and the presence of flammable materials such as oils and fats.

Exhaust duct often accumulate fats and oils over time, which can be dangerous. Excessive warming of these pipes can cause an ignition, leading to tragic consequences. The Firefighters Code requires the installation of a CO2 center to combat the start of the flames. However, the failure of these centrals is not uncommon, either by inadequate maintenance, problems in recharge or even by their absence, which is in disagreement with the fire department normatives.

Another frequent problem is forgetting to turn off equipment at the end of work or activities. Similarly to the ignition in excessive temperature exhaust ducts of a grill, electric fryers or ovens can also cause fires if they remain connected for a prolonged period.

Another frequent problem is forgetting to turn off equipment at the end of work or activities. Similarly to the ignition in excessive temperature exhaust ducts of a grill, electric fryers or ovens can also cause fires if they remain connected for a prolonged period.

The fat that accumulates in hoods and ducts acts as fuel, feeding ignition and enhancing fire to catastrophic proportions.

In any case, any intervention, either through the CO2 Central, or another fire fighting system such as sprinklers, is measured by a preventable situation at any quote as they cause large -scale damage to damage to facilities and equipment, interruptions of operation, and eventually patient deaths.

ELECTRICAL FRAMES AND CIRCUITS

The second largest cause of fires is heating connections and power cables caused by overload and poor contact.

Generally, institutions add equipment and consumption relevant to existing facilities and are not concerned with conducting a load study or installed infrastructure use limit. During summer, especially in tropical cities, where room temperature exceeds 40ºC, an installation near its load limit (current) can easily overheat and start a short circuit usually followed by large ignition and fire.

Poor contact of terminals and cables can also lead the fire at peak use where the current and system requirement are maximum.

The traditional form of prevention of frames and electrical circuits is by manual periodic inspection that includes circuit thermography. Basically, the technical team points to portable infrared temperature meters to gauge at inspection the temperature of the bus and cables. However, this method is not 100% safe because it provides only one sample of the state of the bus at a given time of day that does not necessarily represent the peak of use.

That is, the incidence of fires is not uncommon even with manual thermography procedures.

If the fire was inevitable, it is necessary to control it

Another major problem is the proper functioning of fire control systems.

CO2 and FM automatic extinguishers

During an event, CO2 automatic extinguisher systems or FM gases can be automatically triggered to put out a fire start. But because they are never used, these systems are often discharged or closed without the proper knowledge of the establishment's operational team. During an emergency, drive failure can turn a small event into large proportions.

Sprinklers systems

Depending on the type of installation, sprinkler systems, also with automatic drive, are mandatory. However, for proper functioning during a fire onset, the correct pressurization of the fire fighting system (SCI) is required. If the network is not properly pressurized and with pumps ready for use, the sprinkler system will not be able to circumvent the initial fire.

Similar to automatic extinguishing systems, these systems also risk being closed or with automatic pumps off, preventing their drive during emergency.

Water reserves

Another extremely important item is the reserve of fire for fire. Buildings and commercial establishments need to have a fire -fighting water reserve. This reserve is guaranteed by a water exit level differential, where the most shallow is normal supply and the deepest is for the fire reserve. By terrible coincidences, and human error in maintenance, often during the washing or maintenance of the boxes, the establishments are without the minimum water level or not maneuvering the minimum level of the box after washing leaving the level below the minimum reserve during a SUPPLY scarcity.

Generators

Generators are essential for the continuity of hospital operations, especially during a fire that can lead to the interruption by the concessionaire. Energy is critical to triggering fire fighting systems and especially water pumps.

These equipment depends on several factors such as fuel, batteries in good condition for starting, oil quality, among others that can prevent the generator from starting at the crucial moment. Preventive maintenance may not be sufficient to ensure its functioning and energy failure becomes a decisive factor between the life and the death of patients.

With so many risks, how can we avoid these events?

There is only one way to prevent and anticipate these events: constant state information of all critical facilities. Several studies in hospitals indicate that the standardization of communication and increased process surveillance reduces the incidence of error, increases reliability and safety, whatever the process.

The big problem is what to do to implement a 24 × 7 surveillance of so many physically separated equipment, with distinct technical characteristics that require specific knowledge of energy, generation, hydraulic, gases, etc.

Unfortunately, it is economically unfeasible to displace or implement duty teams for continuous supervision of each of these subsystems.

The solution is then continuous monitoring to send alerts to the maintenance team.

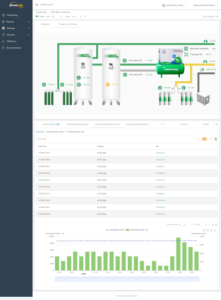

Bridgemeter Intelligent Infrastructure Monitoring

The Bridgemeter platform exemplifies innovation in this area, offering connection capabilities and continuous monitoring for any type of equipment or sensor. This tool is vital in hospital environments, where equipment failures can have serious consequences.

Critical variables such as load and consumption, bus temperature, tanking, line pressures, and equipment operating status are continuously watched. These data are analyzed in real time to identify any deviation that may indicate a fire -prone condition.

Predictive analysis uses performance data to identify patterns and trends that suggest the need for predictive maintenance. Alerts enable proactive interventions, minimizing the risk of fires caused by overload or systems defects.

In addition to improving safety, these proactive interventions contribute to prolonging equipment life and increasing the operational efficiency of hospitals. Predictive -oriented maintenance not only ensures a safer environment, but also optimizes the use of resources and reduces emergency failure and repair costs.

Monitoring in hospital kitchens

Several parameters can be monitored in a hospital cuisine to ensure its proper functioning:

- Hood temperature: either by duct temperature or preparation surface by infrared, the system detects temperatures outside considerable limits

- EQUIPMENT STATE: Fryer, ovens or any other equipment that has a turn on/off may serve as a information basis for risk assessment.

- Fat Incustation Level in ducts: Very important factor that may indicate the need for cleaning by eliminating one of the main fuel fuels and fires in kitchens.

Monitoring of Tables and Electrical Circuits

Through continuous monitoring of bus temperature at strategic points it is possible to evaluate the network use limit safely even under adverse conditions such as summer days and overload of the electrical system. Bridgemeter identifies the temperature trend of the bus and may indicate the need for equipment relocation before this heating generates a short circuit. The constant occurrence of heating may indicate bad contacts or the need for the framework.

Monitoring of fire fighting systems

The system monitors the operation of sprinkler, checking water pressures and tightness of the line, as well as evaluating the status of water pumps and identifying leaks, all essential for maintaining the necessary pressure in the system. This data is crucial to maintaining the fire fighting system ready for immediate use.

In addition, Bridgemeter supervises water reservoir levels for firefighting, ensuring that there is enough volume for an effective response. Automatic alerts inform the technical team about any deviations, allowing fast and efficient corrective actions.

This integrated monitoring significantly increases safety, ensuring that all elements of the fire fighting system work properly when needed.

Monitoring of generators

Above-Net Bridgemeter ensures effective operation of generators through comprehensive monitoring that includes not only part conditions, but also fuel levels, battery and oil quality.

Conclusion

Integrating Bridgemeter into a hospital infrastructure represents not only a reinforcement in fire safety, but also a significant improvement in operational efficiency and a substantial cost reduction.

Above-Net IOT Solution redefines the monitoring of hospital environments, providing a predictive intelligence layer with safety and effectiveness.

This approach not only preserves lives, but also safeguards the valuable hospital resources, ensuring the continuous provision of essential health services to the community.

By implementing Bridgemeter, hospitals not only mitigate risks, but also strengthen their ability to quickly respond to emergencies, thus promoting a safer and more resilient environment for patients, employees and visitors.

Catalog

Want to know more about how to conduct intelligent management of hospital infrastructure?

Then download our catalog to explore how IoT monitoring of the hospital infrastructure improves patient care. Find out smart preventive monitoring solutions with Bridgemeter.