In the era of Industry 4.0, machine and equipment manufacturers are increasingly aware of the importance of monitoring and predicting problems. This type of information is essential for both the factory's maintenance team and the end customer's operational team.

Many companies have taken the initiative to create complete systems development lines to meet the growing demand of Industry 4.0. But is this initiative really worth it? In this article, we will address the challenges of this endeavor and assess whether it is in fact advantageous.

The Technical and Financial Challenges in Implementing Industry 4.0 Solutions

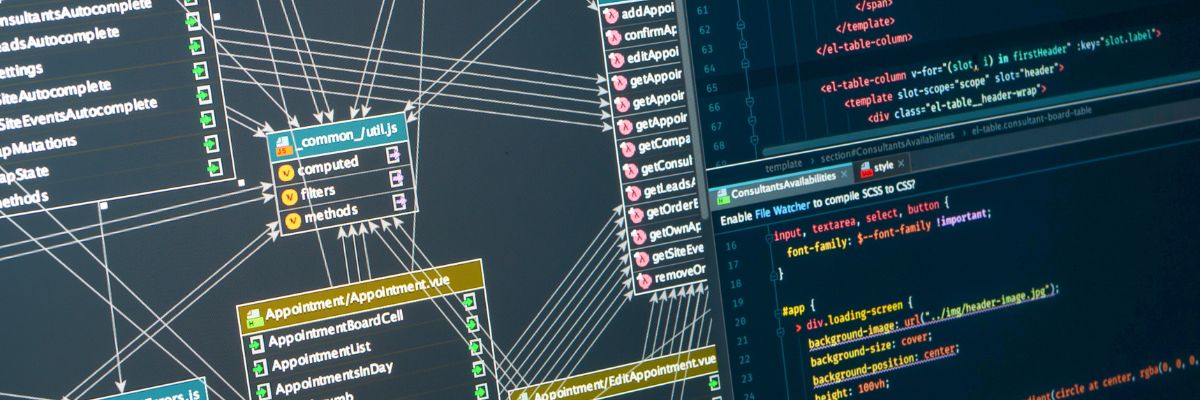

The decision to invest in advanced solutions for Industry 4.0 brings with it a series of technical and financial challenges that cannot be underestimated. One of the main obstacles is the high cost associated with the development and implementation of these technologies. Creating robust and integrated systems requires significant investments in infrastructure, software, and, most importantly, specialized talent, such as automation engineers, software developers, and data analysis specialists.

In addition to the direct financial costs, companies need to consider the time required to develop and implement these solutions. The development process can be long and complex, requiring rigorous testing and constant adjustments to ensure that the system meets the expectations and needs of the critical application market. This development time can impact the launch time of new products, delaying market entry and potentially resulting in a loss of competitiveness.

Another relevant technical challenge is the integration of new systems with existing infrastructures. Many factories operate with equipment and technologies that were developed before the advent of Industry 4.0. Integrating these technologies with legacy systems can be a complicated process, requiring in-depth knowledge of both old and new technologies. Furthermore, end customers today are looking for systems that are compatible not only with the equipment provided by the manufacturer, but also with other devices already installed in the plant. Without adequate integration, there is a risk of creating information silos, where data does not flow efficiently between systems, compromising the potential for predictive analysis and automation.

Other technical development challenges:

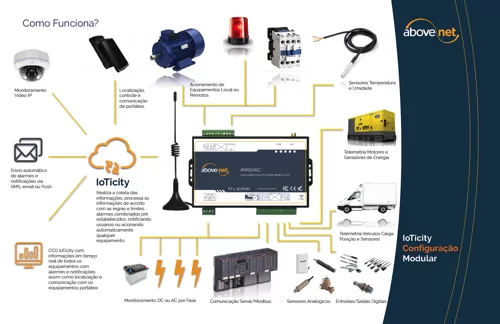

- Complex Architecture : A robust IIoT system requires integration between multiple layers including communication devices, protocols, data, applications and processes.

- Security : With the increase in cyber attacks, ensuring data and system security is crucial and extremely complex.

- Scalability : As more devices are added, the system must be able to scale without losing performance.

- Integration : The system must be able to integrate with different types of controllers, sensors, protocols and existing systems.

- Data Analysis : Implementing intelligence algorithms for predictive analysis requires specific expertise in data science.

- Continuous Maintenance : The system needs constant updates, bug fixes and evolutions to new technologies.

The Importance of Predictive Analytics and Continuous Monitoring

Despite the challenges, the benefits that Industry 4.0 offers are substantial. Predictive analytics and continuous monitoring are central components of these solutions, allowing machine and equipment manufacturers to offer added value to their customers by collecting operational data from their machines. Using intelligent sensors and algorithms, it is possible to detect signs of wear or impending failures before they turn into larger problems. This not only improves equipment reliability and availability, but also reduces maintenance, travel and repair costs, creating a positive value cycle for everyone involved.

Furthermore, continuous monitoring allows the collection of large volumes of operational data, which can be used to optimize equipment performance in real time. By analyzing this data, manufacturers can identify usage patterns and adjust operating parameters to maximize energy efficiency, extend component life, and reduce resource consumption.

The Need for Flexibility and Adaptability

In an environment of constant technological evolution, flexibility is an essential characteristic for any system developed in the Industry 4.0 era. Solutions need to be designed in a modular way, allowing for upgrades and expansions as new technologies emerge or market needs change. This means that, in addition to developing innovative technologies, companies need to adopt a mindset of continuous innovation, where adaptation and constant improvement are seen as integral parts of the development process.

Adaptability is also crucial in the context of different industrial sectors. Each sector has its own specificities and challenges, which requires solutions to be customizable to meet the particular needs of each client. A solution that works well in an automobile industry may not be equally effective in a food manufacturing plant, for example. Therefore, machine manufacturers need to ensure that their solutions can be tuned and customized to deliver the best performance in a variety of industrial contexts.

The Best Strategy in the Era of Industry 4.0

While investing in Industry 4.0 technologies may seem like a tempting opportunity for machinery and equipment manufacturers, it is important to consider the risks and challenges involved. When deciding to develop their own technological solutions, many companies end up diverting their focus from the operational core, facing the need for continuous and high investments to maintain and update these systems. This deviation can result in an overload of resources, in addition to requiring constant adaptation to rapid technological changes, which can become an expensive and exhausting task in the long term.

Instead of investing in in-house development, it makes much more sense to opt for an already established industrial IoT monitoring platform. These platforms are designed to provide continuous updates and guarantee unlimited compatibility with different systems and equipment. Furthermore, they offer a horizontal view of the entire industrial plant, instead of vertical monitoring focused only on equipment manufactured by the company itself. This means that customers can monitor and optimize their entire operation in an integrated and efficient way, without the limitations imposed by internally developed solutions.

Advantages of this approach include:

- Focus on Core Business : Allows the company to direct its resources to what it does best – manufacturing high-quality machines.

- Access to Expertise : Expert partners bring years of experience and in-depth knowledge in IIoT software development, ensuring high-quality solutions.

- Cost Reduction : Eliminates the need to invest in an internal software development team and IT infrastructure, significantly reducing operational costs.

- Agility in Time-to-Market : Ready-made and tested solutions can be implemented much faster than developing a system from scratch, speeding up time to market.

- Robust Solutions : Specialized companies offer mature, extensively tested and reliable solutions, providing greater security and efficiency.

- Scalability : Partner solutions often offer greater flexibility to grow with demand, allowing you to efficiently adapt to market changes.

The Bridgemeter Case

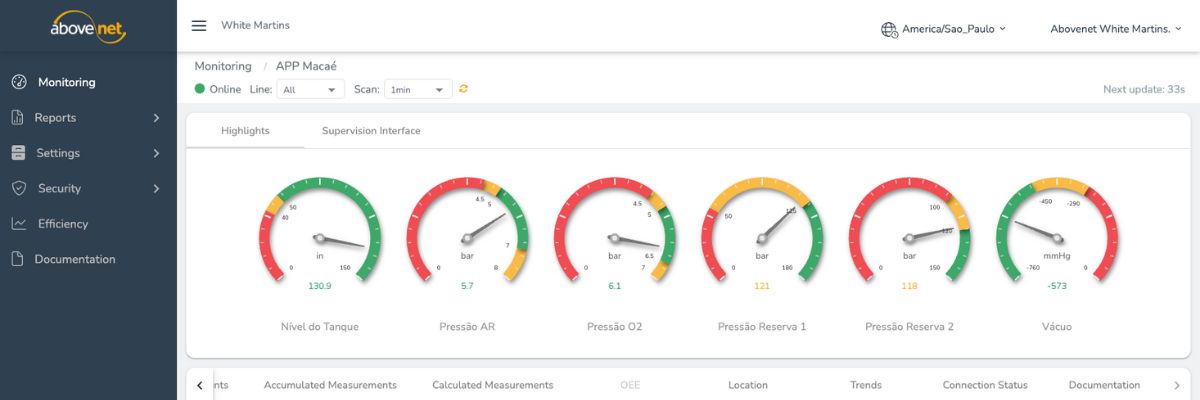

Above-Net , with its Bridgemeter solution, perfectly exemplifies the benefits of a strategic IIoT software partnership. Bridgemeter is the complete predictive monitoring platform, which effectively integrates with different types of machines and equipment.

By adopting a solution like Bridgemeter , machine builders can provide their customers with:

- Real-time monitoring : Continuous monitoring of machine performance to ensure efficient operation.

- Predictive analytics : Tools for preventative maintenance, reducing downtime and repair costs.

- Valuable insights : Detailed, segmented information for the manufacturer and end customer about equipment operation and efficiency, enabling more informed decision-making for both parties.

- Simplified integration : Easy compatibility with existing systems and infrastructures, avoiding information silos.

- Drag & Drop Interface : Allows instant configuration of rules, synoptics and graphics on the platform.

- Robust data security : Industrial-grade protection to ensure data confidentiality and integrity.

- Business intelligence : Analytical capabilities that help identify opportunities for improvement and optimization.

- Additional revenue generation : Opportunity to resell the solution to end customers, creating a new source of income.

Conclusion

By using an industrial IoT monitoring platform, companies not only reduce their costs and development efforts, but also ensure that their customers receive a high-quality solution that is always up to date and capable of keeping up with technological innovations. This approach allows manufacturers to focus their efforts on what they do best – developing and manufacturing cutting-edge machines and equipment – while leaving the complexity of monitoring and predictive analytics in the hands of IoT experts.

Want to know more about how Bridgemeter can revolutionize the monitoring of your machines and equipment? Download our complete catalog now and discover all the features and benefits of this innovative solution and take the first step towards transforming your predictive maintenance. Don't miss the opportunity to take your business to the next level with leading industrial IoT technology!