In industry, operational inefficiency can cause catastrophic problems, resulting in unexpected downtime, missed deadlines and, eventually, significant financial losses. These challenges are compounded by the lack of visibility and proactiveness of traditional OEE (Overall Equipment Effectiveness) systems, which still predominate in many industrial environments.

One of the biggest pains faced by industries is the lack of timely communication about operational problems. In traditional systems, production managers only become aware of machine failures or downtime if they are next to the machine or at the end of the shift, when it is too late to correct and avoid delays in deliveries. For example, a machine may stop unexpectedly, and the manager will only discover this at the end of the day, making it impossible to make up for lost time.

One of the biggest pains faced by industries is the lack of timely communication about operational problems. In traditional systems, production managers only become aware of machine failures or downtime if they are next to the machine or at the end of the shift, when it is too late to correct and avoid delays in deliveries. For example, a machine may stop unexpectedly, and the manager will only discover this at the end of the day, making it impossible to make up for lost time.

Additionally, processing machine efficiency (OEE) information using traditional systems is often manual and involves working with Excel spreadsheets to generate historical reports. This process is not only time consuming, but also increases the risk of human error, not to mention delays in detecting the problem. The lack of automation and proactivity in this process implies late identification of delays and production problems with very low chances of reversal only after the problem arises.

Another significant problem is the lack of contextualization of OEE data. Traditional OEE systems only measure machine productivity, without considering underlying factors that can affect efficiency, such as mechanical failures or maintenance issues. This prevents a complete understanding of the causes of drops in OEE, making it difficult to implement effective solutions. For example, a machine may operate at low efficiency due to constant overheating, but because the OEE system does not monitor temperature, this root cause goes unnoticed.

A particularly problematic aspect is that OEE indicators are displayed on the machines themselves or on panels located at specific points in the factory. This requires the production manager to physically travel to these panels to check the status of indicators, a time-consuming process that can result in delays in responding to critical issues. In other words, if a manager or operator is not paying attention to the machine's local panel, performance deviations indicated by the traditional OEE system may go unnoticed, running the risk of delays in corrective actions. It is equivalent to “driving in the rear view mirror”, reacting to problems only after they have already occurred.

A particularly problematic aspect is that OEE indicators are displayed on the machines themselves or on panels located at specific points in the factory. This requires the production manager to physically travel to these panels to check the status of indicators, a time-consuming process that can result in delays in responding to critical issues. In other words, if a manager or operator is not paying attention to the machine's local panel, performance deviations indicated by the traditional OEE system may go unnoticed, running the risk of delays in corrective actions. It is equivalent to “driving in the rear view mirror”, reacting to problems only after they have already occurred.

How to solve the problem?

Several companies develop panels and solutions using third parties or their IT department, but these solutions are attempts to integrate a process that requires more than a few integrated technologies. Furthermore, most of the time, these activities are deviations from the company's main activity, resulting in overload of professionals with a solution that continues to fail to meet production management's expectations.

The ideal solution must include an application capable of monitoring the variables of each machine on the production line in real time, cross-referencing information and alerting those responsible in a scalable, autonomous and proactive way. In other words, it should eliminate the need for physical presence or focus on any monitoring panel. In a simple and targeted way, the system must send an auditable notification to users capable of making decisions that avoid losses to the production line.

Furthermore, most of the problems faced in terms of equipment efficiency are the effects of machine operational problems (example of heating in this same article). A system that simultaneously monitors machine operating parameters can provide process intelligence and alert the maintenance team before a problem affects production. It means treating cause rather than effect.

The big problem until today was finding a solution capable of addressing all these issues without the prohibitive development cost.

Bridgemeter Solution: Proactive and predictive monitoring of machine health and health.

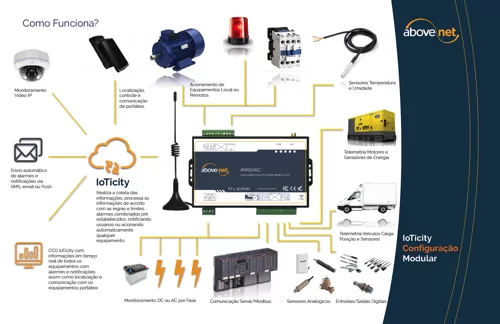

Above-Net 's Bridgemeter was developed to overcome these pain points faced by industries, offering an integrated monitoring solution that goes beyond simply measuring productivity. With Bridgemeter , managers have access to a complete and contextualized view of production performance, including all machine operating parameters.

One of Bridgemeter 's main features is its proactiveness. The system sends real-time notifications directly to the production manager's cell phone, allowing him to monitor line efficiency without going to information panels or equipment. This means corrective actions can be taken immediately, minimizing downtime and avoiding significant productivity losses.

Furthermore, the Bridgemeter monitors not only the overall efficiency of the machine, but also critical parameters, among others, temperature, pressure and electrical current. With this integrated approach, it is possible to identify potential problems in advance before unexpected downtime impacts production.

Bridgemeter 's flexibility and interoperability is another big differentiator. The system can be configured to adapt to each customer's specific OEE needs, integrating seamlessly with existing PLCs (Programmable Logic Controllers) or performing calculations after collecting parameters. This flexibility allows Bridgemeter to be implemented in different types of industries and production settings, providing a tailored solution for each scenario.

Additionally, Bridgemeter offers an intuitive, easy-to-use interface that provides clear, actionable views of OEE data. Managers can access real-time dashboards that show alarms about the availability, performance and quality of machines, as well as global OEE indicators. This facilitates informed decision-making and prioritization of corrective actions, continuously improving operational efficiency.

Results

The implementation of Bridgemeter brings a series of tangible benefits to the operation of industries. Firstly, the proactiveness of the system significantly reduces unplanned downtime, resulting in an increase in machine availability and, consequently, production capacity.

Furthermore, the contextualization of operational data provided by Bridgemeter allows for a deeper and more accurate analysis of the causes of productivity drops. This leads to improvements in performance and production quality, increasing overall OEE.

Bridgemeter 's flexibility and interoperability with existing systems also facilitate its adoption, allowing managers to make more informed, data-driven decisions.

In short, Bridgemeter transforms the way industries monitor and manage the effectiveness of their equipment, providing a proactive, flexible and integrated solution. Expected results include greater machine availability, continuous improvement in production performance and quality, and significant reduction in operating costs. By adopting Bridgemeter , industries can achieve a new level of operational efficiency and market competitiveness.