Find out how intelligent monitoring of generator groups prevents critical failures, reduces costs and ensures the reliability of your energy backup.

It was a typical night on duty in a large hospital when the unexpected happened: a total blackout in the region. In a matter of seconds, all lights went out. This was exactly the moment the generator group had been installed. However, when necessary, the equipment remained silent.

In ICU, doctors and nurses ran to maintain vital equipment operating with emergency batteries, while technicians found it too late that the fuel tank was virtually empty - a preventable situation with a proper monitoring system.

This story, unfortunately, illustrates the risks of operating without a smart and predictive monitoring solution. With Bridgemeter, the hospital could have identified and corrected the supply problem in advance, ensuring the continuity of essential care and protecting lives.

This scenario, unfortunately, is not fictitious. It is repeatedly repeated alarming in facilities that depend on generator groups such as backup system. Studies in the US indicate a failure rate of 3% to 4% in these equipment - a seemingly small percentage, but with potentially catastrophic consequences.

In critical environments such as hospitals, industries, data centers and large commercial buildings, continuity of energy supply is not just a convenience but a vital need. A single minute of interruption can generate significant financial losses, compromise essential operations and, at the worst scenario, put lives at risk.

The great challenge of generator groups lies precisely in the nature of their operation: unlike other critical equipment, which work continuously, generators remain inactive until they are indispensable. They are like emergency parachutes - they need to work perfectly the first and only time they are triggered.

Invisible risks

In January 2024, a hospital in Sao Paulo lived moments of panic by having to evacuate his ICU after a fire principle. In another even serious case, a hospital in Rio de Janeiro faced a tragedy when a fire started in a generator resulted in 14 deaths and 97 injured. These are not isolated cases - they are dramatic alerts about the occult risks in apparently safe equipment.

In date centers, where every second of inactivity can cost thousands of reais, the failure of a generator means more than financial losses: it represents the interruption of essential services that affect thousands of users. In the industry, an unplanned stop can lead to the loss of integer production lots, damage to sensitive equipment and, in some cases, even risks to workers safety.

The false sense of security of traditional maintenance

The traditional approach to maintaining generator groups can be compared to taking a monthly photograph of something that changes every minute. During periodic inspections, technicians check fuel levels, test batteries and perform standardized procedures. The generator is turned on for a few minutes, data is collected, and everything seems to be working perfectly. However, the next day, everything may be different.

“It's surprising how seemingly simple situations can compromise an entire backup system,” says an engineer with two decades of industry experience. “I have witnessed cases where someone had to start a truck and temporarily removed the generator's battery. When replacing it, a poorly compromised connection compromised the system. In another situation, employees used the generator's fuel for other purposes, leaving the tank dangerously low. ”

These inspections cover only 1% of total operating time, leaving the real state of the unknown equipment during the other 99% of the time. It's like driving a car whose instrument panel only works 15 minutes a day.

In short, the limitations of traditional maintenance include:

- Insufficient temporal coverage : Periodic inspections cover less than 1% of operating time, leaving the equipment without supervision for 99% of the time.

- Excessive dependence on human intervention : subject to errors and a limited view to the inspection interval.

- Lack of continuous detection : Problems that arise between inspections can go unnoticed to the critical moment.

- High Costs : Frequent displacements for routine checks represent significant expenses.

- Lack of predictability : inability to anticipate failures before they occur.

- Lack of real -time monitoring : Critical parameters are only verified during inspections.

- Historical Record Difficulty : Lack of continuous data for trend analysis.

- Reactive Response : Problems are only identified after they occur.

- Inefficient Maintenance : Fixed maintenance intervals do not always correspond to the actual use of the equipment.

The Intelligent Monitoring Revolution with Bridgemeter

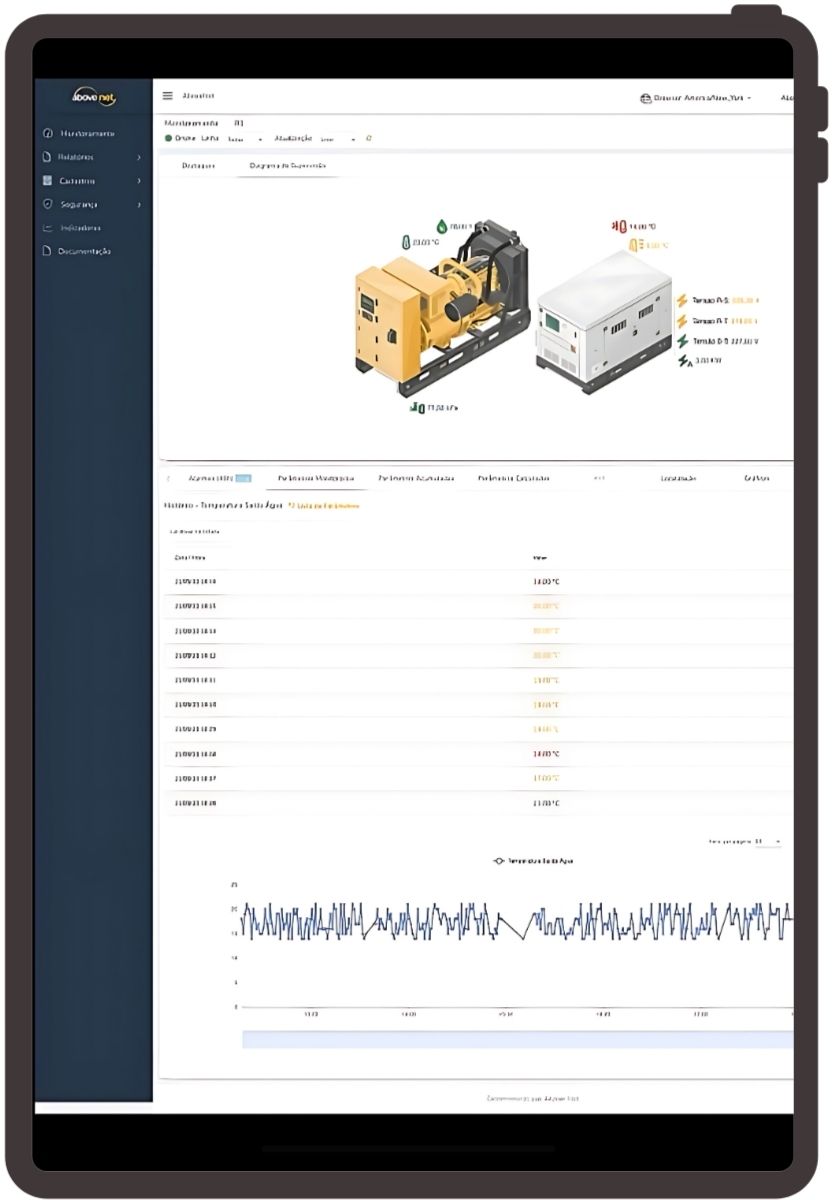

It was to face these challenges that Above-Net developed Bridgemeter , a solution that transforms the way we monitor and manage any teams, in particular, generator groups. More than a monitoring system, Bridgemeter acts as a tireless guardian, overseeing each aspect of the equipment 24 hours a day, 7 days a week.

The system operates in multiple layers of protection. In the most basic layer, continuously monitor critical parameters such as fuel levels, battery status, engine and oil temperature, pressures and electrical data. However, it is in the intelligence layer that Bridgemeter really stands out.

Imagine, for example, a sudden drop at the fuel level at dawn without the generator being triggered. In seconds, the system identifies anomalous behavior and notifies the team responsible for the Bridgemeter App Mobile, issuing alerts of a possible leakage or fuel theft, preventing a possible future crisis. Similarly, subtle battery degradation patterns, imperceptible in conventional tests, are detected and reported before causing failures.

Bridgemeter allows real -time monitoring of the following critical parameters:

Engine monitoring :

- Engine and oil temperature

- Oil pressure

- Engine rpm

- Himeter

- Cooling system

- Oil quality

Electric Monitoring :

- Voltage

- Current

- Frequency

- Active and reactive power

- Power factor

Resource Monitoring :

- Level and fuel consumption

- Battery state and load

- Load and demand for use

- Estimated autonomy

- Average consumption

Environmental Monitoring :

- Ambient temperature

- Smoke detection

- Leakage sensors

- Ventilation

Bridgemeter offers continuous and intelligent supervision, allowing for problems and significantly increasing the safety and reliability of backup systems.

The intelligence behind monitoring

Bridgemeter differs by its predictive analysis capacity, going beyond simple data collection by interpreting it in the specific operational context of each client. When a generator is in operation, for example, the system monitors and simultaneously analyzes dozens of parameters, adapting to the type of operation and the individual needs of the installation.

This intelligence is not limited to a single equipment. In environments with multiple generators, Bridgemeter coordinates tests and operations in an integrated manner, ensuring the balanced load distribution and the proper exercise of each unit.

In short, Bridgemeter offers:

- Detection of anomalous variations that indicate potential problems

- Identification of degradation trends before they result in failures

- Calculation of autonomy based on real consumption

- Automatic alerts for critical conditions

- Programmed maintenance according to the actual condition of the equipment

Bridgemeter is a solution that adapts to the requirements of each operation, maximizing the safety and reliability of the backup system and increasing the efficiency of preventive maintenance.

This intelligence extends beyond individual equipment. In multi -generating facilities, the system can coordinate tests and operations, ensuring that the load is properly distributed and that the equipment is exercised in a balanced manner.

In short, Bridgemeter gets:

- Detect abnormal variations that indicate potential problems

- Identify degradation trends before they cause failures

- Calculate autonomy based on real consumption

- Generate automatic alerts for critical conditions

- Programming maintenance based on real condition

Transforming Maintenance on Prevention: The Benefits of Intelligent Monitoring with Bridgemeter

Bridgemeter's intelligent approach revolutionizes the experience for both end users and maintenance companies. Previously, technicians needed frequent displacements for routine inspections; Now they can focus on truly necessary interventions oriented by precise data and predictive analyzes.

For end users , Bridgemeter offers:

Operational reliability:

- Substantial reduction in the risk of unexpected failures

- Guarantee of system readiness in emergency situations

- Continuous monitoring 24/7 without team team needs

- Early detection of potential problems

Economy and efficiency :

- Cost reduction with optimized preventive maintenance

- Elimination of unnecessary displacements

- Efficient management of fuel consumption

- EXPECTION LIFE EXTENSION

Security and control :

- Prevention against fraud and fuel thefts

- Monitoring critical environmental conditions

- Detailed record for audits

- Automatic alerts in real time

For infrastructure managers and clinical engineers , Bridgemeter represents the tranquility of an automated operational guardian. Through an intuitive, computer, tablet or smartphone interface, technicians can monitor the status of equipment in real time, receive proactive alerts and make sure their backup systems will be ready when necessary.

For maintenance companies , the benefits are equally powerful:

Operational Optimization :

- Significant reduction in displacement costs

- More efficient planning of preventive maintenance

- Remote diagnosis I need problems

- Efficient management of the equipment fleet

Contract Management :

- Precise control of operating hours

- Detailed documentation of the services provided

- IMPROVEMENT IN THE QUALITY OF SERVICE

- Reduction of emergency calls

Bridgemeter redefines efficiency and reliability in generator monitoring, transforming the maintenance of a reactive process for a predictive and preventive strategy.

Conclusion

The evolution of technology allows us to perform today what was once unimaginable: transforming traditionally “blind” equipment into intelligent and integrated systems. Bridgemeter goes beyond a monitoring solution - it represents a true revolution in critical equipment management.

In a scenario where energy reliability becomes increasingly essential, we can no longer rely on old -fashioned methods to manage our most important resources. Intelligent and predictive monitoring is not just a choice - it is a requirement for organizations that prioritize the safety and reliability of their operations.

Application

Would you like to ensure the efficiency of your generator group and prevent unexpected failures?

Now download the Bridgemeter catalog for monitoring generator groups and find out how our intelligent monitoring solution can transform the management of your generator groups.