What is thermal monitoring for?

The main causes of fire and reduce useful life in electrical equipment are poor contact or defective connections, where temperature increase is the main symptom and an indicator that a possible imminent problem. Thermal monitoring allows organizations to detect symptoms in these connections that, without intervention, could lead to electrical interruptions or, worse, to a fire. Without early identification, the deterioration of a defective electrical connection increases more thermal resistance and therefore generating a higher temperature, which ends up resulting in thermal escape and finally a complete failure. The next step for a collapse is a phenomenon known as the electric arc followed by a fire, or even an explosion. At this point the unexpected stoppage of the plant is inevitable beyond of course, of catastrophic consequences, such as the total destruction of the equipment or even death or personal injuries.

How to solve the problem?

Continuous thermal monitoring is the evolution of periodic infrared inspection.

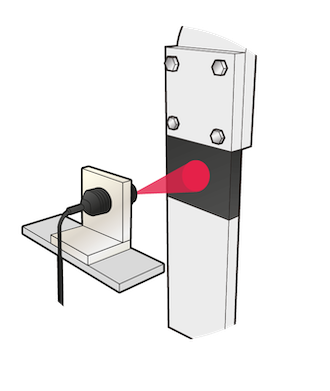

Traditionally, maintenance teams make inspections with infrared reading equipment to detect punctual warmths that can evolve into situations such as the one described above. However, this monitoring represents static information that does not indicate the real trend or situation of infrastructure or equipment connection. Punctual reading can be done at a certain period of the day when the load is shorter or on a winter day when the outside temperature does not influence the operation. To avoid this type of reading where the inspection result does not represent all system behavior, such as a peak situation and consequently a risk of operation, we recommend continuous thermal monitoring.

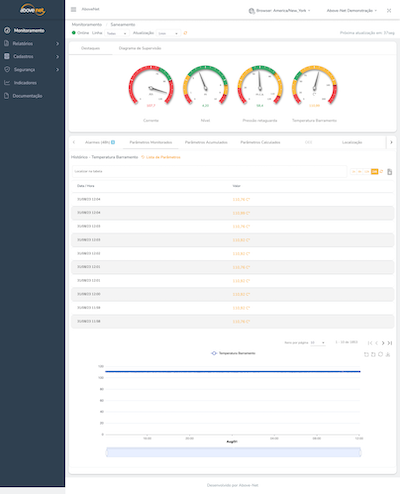

Through sensors installed on electrical equipment, the continuous thermal monitoring solution offers 24 hours a day protection, 7 days a week, with integrated temperature data and notifications for the real -time maintenance team of critical electrical actives.

It allows electrical maintenance teams to provide failures, protect electrical equipment and optimize performance by reducing maintenance costs. With the interruption of energy supply representing an increasingly critical threat to organizations, the need for innovative thermal monitoring solutions for the industry maximizes activity time through fault forecasting before they occur. The additional benefits offered by this technology include greater personnel safety and longer asset life.

Continuous thermal monitoring allows the electrical engineering team:

- Predict electrical failures and optimize maintenance;

- Transmits data in real time in a structured way

- Notify maintenance technicians proactively in reading behavior change

- Increase reliability and maximize activity time;

- Reduce Opex's cost and increase operational efficiency;

- Reduce risks and increase the safety of staff and operation.

As we increase awareness of the benefits of thermal conditions monitoring technology, it is easier to monitor mission critical electrical infrastructure.

Thermal monitoring sensors can be installed in electrical assets such as BT/MT regulators, motor control centers (CCMs), uninterrupted power sources (UPS), power distribution and transformers.

- These essential electrical actives are used in a wide variety of industries, including:

- Oil and gas

- Mining

- DATA CENTERS

- Sanitation and wastewater

- Food industry and drinks

- Retail logistics

- Critical infrastructure

- Manufacture

- Hospitals

Surprisingly, the use of an industrial IoT platform for high quality continuous thermal monitoring represents an economy and very high ROI for operation because the installation is usually neglected and the unique operation is always subject to unforeseen events.

Therefore, the continuous thermal perception of the main assets allows the prevention of possible threats, such as unexpected stops, expenditure replacement and replacements of electrical assets and the risk of injuries to the people involved in the operation.

The evaluation of the condition of electrical equipment:

In addition to these high -risk scenarios, energy is the most essential input for any organization. Failure can result in energy loss for critical systems, which, in turn, depending on the nature and/or severity of the failure, impacts inactivity time, productivity loss, repair costs or replacement. An electrical equipment is inherently dangerous; A heating failure can lead to serious injuries, fires, infrastructure damage or even death.

ABOVE Above-Net has a partnership with Exertherm and offers in conjunction with Bridgemeter®, continuous energy monitoring for critical infrastructure.