Check out Bridgemeter's crucial importance in predictive monitoring during the Lameirão Elevator modernization operation, the largest in the world.

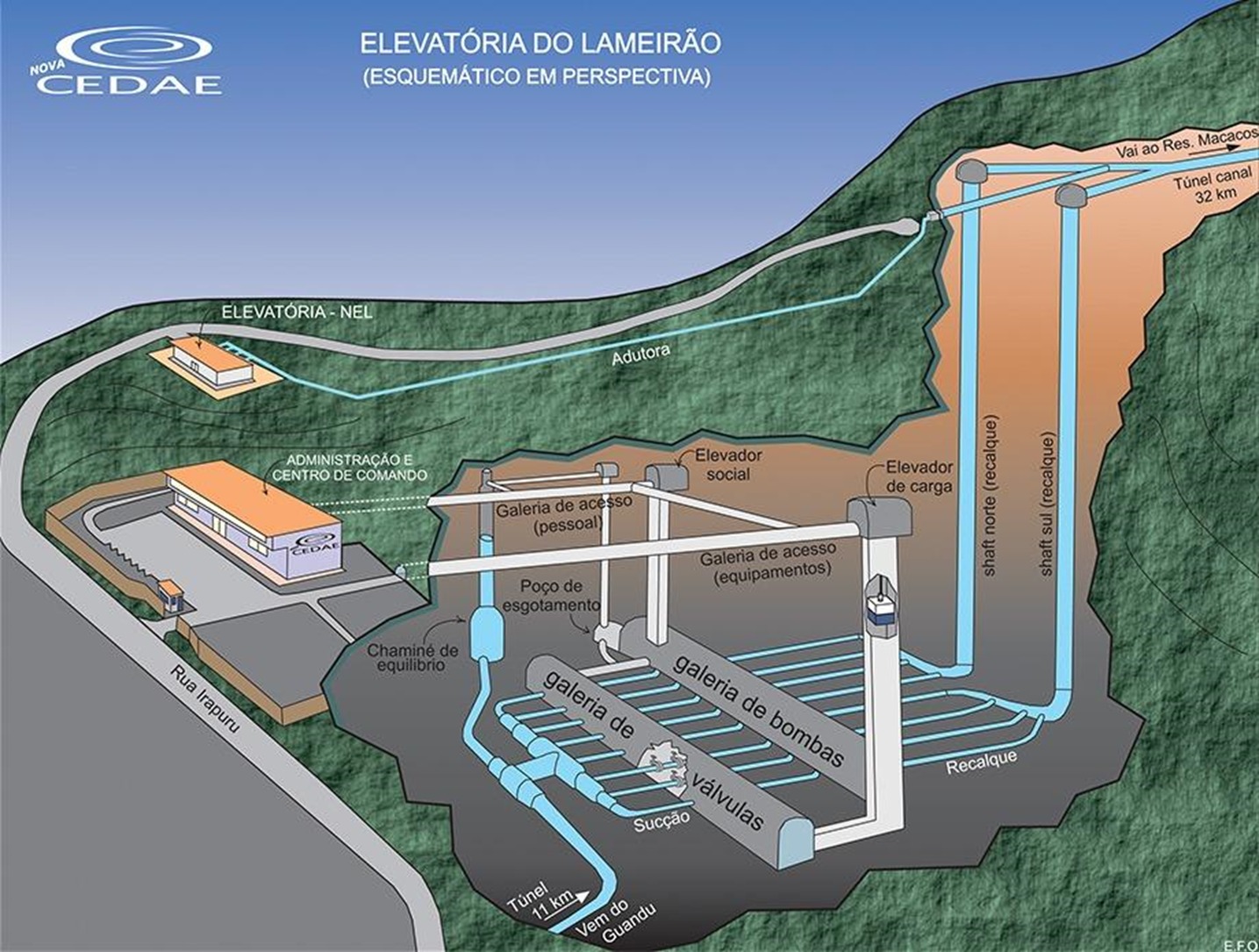

The Lameirão Lift , located in Santíssimo, Rio de Janeiro, is an extraordinary engineering work. Inaugurated in 1966, it is recognized as the largest underground elevator of treated water in the world. This monumental structure plays a vital role in the water supply system of the city of Rio de Janeiro and the metropolitan region, being often referred to as “the work of the century” due to its importance and scale.

With high power engines, capable of pumping 27,600 liters of water per minute, the Lameirão lift is essential for the transport of treated water, meeting the growing demand of the local population. Its ability and advanced technology make it a critical component of Rio de Janeiro's water infrastructure, reflecting both the advances in civil engineering and the challenges of water resource management in densely populated urban areas.

Modernization of the Lameirão lift: the exchange of two engines

In August 2024, Cedae carried out a major operation: the replacement of two of the main motors of the Lameirão elevator. This modernization project has an investment of approximately R $ 15 million and marks a historic moment for the state sanitation infrastructure.

The new installed engines have an impressive 6,900 liters of water per second, representing a significant advance in efficiency and reliability. This update not only ensures greater operational safety, but also promises a substantial reduction in energy consumption, estimated at 1.1 million kWh per month, which translates into an annual economy of about $ 4.9 million.

The replacement of these equipment is part of a broader plan of Cedae investments to ensure the resilience of the lameirão pumping system and ensure water supply for state development in the coming decades.

Complexity and challenges of the operation

The change of engines in an installation of the size of the Lameirão lift is an extremely complex and challenging operation. Several factors contribute to this complexity:

- Operation Scale : The replaced engines are huge, with 9,000 hp each, and are located 64 meters deep.

- Logistics : The transportation of the new factory engines in Santa Catarina to Rio de Janeiro was an operation that lasted six days, requiring special escort.

- Continuity of the service : The lift cannot stop completely, as it is responsible for pumping half of the treated water that supplies the metropolitan region of Rio de Janeiro. The operation had to be performed to minimize any interruption in water supply.

- Limited Time Window : The entire replacement process had to be performed within a three -day window, requiring precise and efficient coordination.

- Tests and Validations : After installation, it was necessary to perform a series of tests and validations to ensure the proper operation of the new engines and their integration with the existing system.

- Continuous monitoring : Throughout the process, it was crucial to maintain constant monitoring of various parameters to ensure the safety and effectiveness of the operation.

Bridgemeter's crucial role during the Lameirão elevatorial modernization operation

In this scenario of high complexity and criticality, the Bridgemeter played a key role. Above-Net intelligent industrial IoT solution , was essential to ensure continuous and reliable monitoring throughout the engine replacement process.

Above-Net is responsible for the remote communication of the Lameirão station and implemented an extraordinary redundancy solution that maximizes the station's SLA (Service Level Add) during the critical testing and validation period. This included the installation of devices and aidal redundancy settings, resulting in virtually uninterrupted communication, with a SLA close to 100%.

In addition to Bridgemeter, BridgeManager, was used to mirror data to the Guandu Operational Control Center (CCO), allowing real -time remote monitoring of critical parameters such as pressures, flow, pump status and levels in scada systems. This real -time monitoring capacity was crucial to ensure that each substitution step was performed safely and efficiently.

In addition, the system allowed the telecommand and monitoring of the pumps, ensuring that the control center could maintain the necessary supervision and control throughout the process. Bridgemeter's ability to process and present data in real time was essential for quick and accurate decision making during operation.

Bridgemeter benefits and resources in complex operations

The success of the Lameirão lift operation highlights Bridgemeter's numerous benefits and resources in complex sanitation :

- Real -Time Monitoring : Bridgemeter offers instant viewing of critical data, allowing quick answers to any anomaly.

- High reliability : With its redundant architecture, the system ensures uninterrupted, crucial communication in critical operations.

- Flexible Integration : Able to integrate with existing SCADA systems, as well as any type of sensors and equipment, Bridgemeter offers a versatile solution to different operational scenarios.

- Predictive Analysis : Using advanced algorithms, the system can predict potential problems before they occur, allowing preventive maintenance.

- Smart Alarm Management : Bridgemeter can be configured to alert operators on specific conditions, prioritizing critical events.

- Decision Support : By providing precise data and real -time analysis, the system assists in making decisions informed during complex operations.

- Scalability : Bridgemeter can be easily expanded to monitor multiple sites and equipment, offering a holistic view of operations.

The choice of Cedae by Bridgemeter for the real -time predictive monitoring of its operations demonstrates the confidence in its ability to deal with critical sanitation infrastructures. This partnership between Above-Net and CEDAE represents a significant step in the modernization and optimization of sanitation operations in Rio de Janeiro.

Conclusion: a successful operation

The successful substitution of the two motors in the Lameirão lift represents a significant milestone in the modernization of Rio de Janeiro's sanitation infrastructure. Bridgemeter's role in this operation was crucial, demonstrating its ability to provide reliable and real -time monitoring in high -critical situations.

The success of this operation not only improved the efficiency and reliability of the Lameirão lift, but also established a new standard for future modernizations in critical sanitation infrastructure. The partnership between Above-Net and CEDAE, supported by advanced Bridgemeter technology, promises a more efficient and sustainable future for water supply in the metropolitan region of Rio de Janeiro.

This success case serves as a powerful example of how intelligently and strategically applied IoT technology, can turn complex operations into remarkable successes, benefiting millions of citizens and preparing cities for future water resource management challenges.

Application

Want to know more about how Bridgemeter can revolutionize your company's sanitation operations?

Download now our free catalog “Intelligent Sanitation Operational Management” and find out how our industrial IoT technology can optimize your processes, reduce costs and increase operational efficiency.

Transform your sanitation infrastructure with Above-NetPT solutions. Do not miss this opportunity to bring your operation to the next level!