A water pump block for an elevatorial pump belonging to a water supply company has been promptly identified thanks to the innovative Bridgemeter of Operational Monitoring Based on the Internet of Industrial Things-IOT provided by Above-Net . The root of the problem resided in a plastic bag that inadvertently entered the bomb.

In a traditional operation, the partial or total reduction of pumping flow would impact the lack of water within hours and the pump and rotor would suffer overheating causing permanent damage interrupting the operation until the repair was performed. In addition, the so -called would only be made emergency after the population's claim or the perception of water shortages in later stages in person or through a traditional monitoring system.

Thanks to Bridgemeter and its intelligent operation monitoring model, the local maintenance team received on their mobile devices, the proactive system notification indicating the pump pressure drop without the need to check the site even before the low level reduction of the next lift.

The platform captures real -time information from any cloud -safe infrastructure sensor type, where through its intersection and intelligence algorithm notifies and scale the problem for immediate performance of the remote teams.

Above-Net 's solution represents an excellent complement to traditional supervision systems as it is more flexible and does not require additional costs for configuration and adjustments to the operation. In fact, in many clients, Bridgemeter operates integrated by adding value to traditional SCADA systems.

Bridgemeter represents an affordable alternative, which enables intelligent operational monitoring of all assets in an integrated manner, regardless of the size or complexity of the operation. According to Marcelo Ramos, CEO of Above-Net, “traditional monitoring systems, such as the SCADA, depend on the human perceptive capacity of the control center to identify problems and then trigger the field team, which often proves to be a slow process and ineffective. Bridgemeter is an intelligent and proactive solution that detects real -time problems and notifies the maintenance team even before causing losses and interruptions. It is also very flexible as it allows intelligence, rules and diagrams to be updated by the customer management team in the tool itself by immediately implementing modifications according to the need for operation. ”

The rapid identification of the problem allowed the team to perform a simple unclogging operation even before the rotor or pump burned. In addition to reducing service time, the company has avoided additional parts of parts, emergency labor and interruption of services that would be significantly higher.

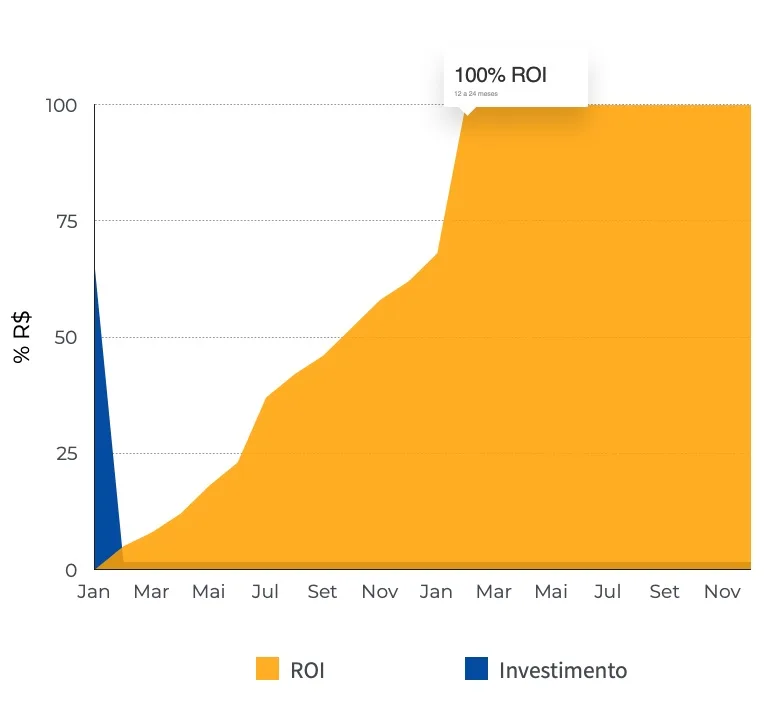

This type of event clearly demonstrates ROI (return on investment) of the Bridgemeter solution that varies only between 6 and 12 months!

Application

Want to know more about how Bridgemeter can revolutionize your company's sanitation operations?

Download now our free catalog “Intelligent Sanitation Operational Management” and find out how our industrial IoT technology can optimize your processes, reduce costs and increase operational efficiency.

Transform your sanitation infrastructure with Above-NetPT solutions. Do not miss this opportunity to bring your operation to the next level!