A indústria atualmente possui uma alta complexidade operacional que dificulta o aumento da eficiência. A tecnologia de manufatura, em sua grande maioria, não avançou no mesmo ritmo dos sistemas de consumo e negócios. E a redução de custo de mão de obra não é mais um fator diferencial. Portanto, é necessário e fundamental, a melhoria de performance e modelo de negócios existentes e maior agilidade no acompanhamento de tecnologias emergentes.

Novas demandas de mercado, regulamentações, concorrência entre outros, criam um cenário desafiador e de incertezas. Dessa forma, as empresas precisam de flexibilidade e facilidade para manterem-se competitivas.

Os sistemas tradicionais responsáveis pelo gerenciamento e monitoramento não possuem uma arquitetura que permita alterações de forma rápida e dinâmica ou muito menos que consiga antecipar e notificar eventos de falhas de forma preditiva e proativa.

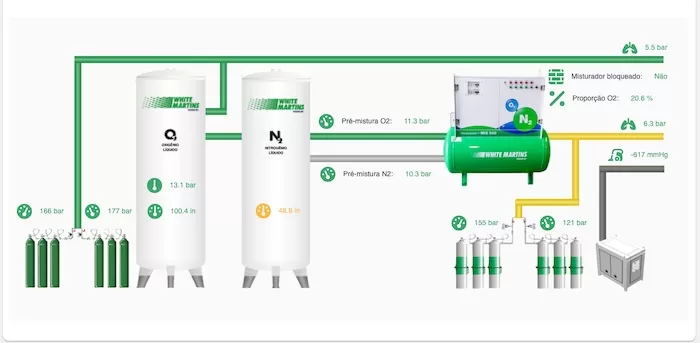

Outro aspecto importante é a conectividade com uma variedade de equipamentos. Para alcançar a eficiência operacional, é preciso convergir todas as leituras de qualquer subsistema existente em uma mesma aplicação proporcionando uma visão global da operação.

Este último trás por consequência, a conectividade com diversos tipos de protocolos. Uma solução de IIoT não pode estar limitada a um número seleto de protocolos, muito menos a grupos de protocolos mais usados atualmente. É necessário conectar equipamentos e sistemas legados, garantindo a interoperabilidade e convergência para uma mesma plataforma com o passado, presente e com o futuro.

Quando a Above-Net iniciou o desenvolvimento do Bridgemeter em 2014 percebeu esse desejo e requerimento do mercado e construiu uma arquitetura sólida modular em camadas que permite a total interoperabilidade de equipamentos.

Além de opções de conectividade e meios de transmissão (Celular, LoRa, NB-IoT, WiFi…), hoje a plataforma oferece mais de 140 tipos de protocolos que permitem aplicar o conceito Plug and Play de qualquer equipamento ou sensor, mesmo que legados. Com tanta flexibilidade, é possível passar por um processo gradual de transformação digital com custos ajustados à realidade de investimento do cliente.

A partir da coleta das informações, todos os dados são armazenados de forma estruturada permitindo a interligação com diversas outras ferramentas do mercado de forma horizontal para análise específica dos dados.

Outra dificuldade identificada pela Above-Net em 2014 era a capacidade de antecipar falhas e comunicação ao usuário de eventos em parques tão extensos de equipamentos. O modelo atual de centro de controle é impraticável e ineficiente pois dispersa a atenção para eventos que em 90% do tempo funcionam corretamente. O desafio é não perder nem deixar de transmitir a informação crítica o mais rápido possível para o time encarregado de uma alteração em qualquer leitura seja qual for o tamanho da infraestrutura monitorada.

O Bridgemeter utiliza técnicas modernas de notificações em tempo real que garantem a entrega da informação de forma proativa. Ou seja, mesmo que o operador esteja em uma pausa para o café ou que seu painel do centro de controle não comporte mais equipamentos, o sistema identifica de forma automática e notifica todos os envolvidos com um plano de ação.

De fato, os clientes Bridgemeter percebem uma economia substancial de tempo de atendimento em comparação ao mesmo processo antes da utilização da solução. Nesses casos, os times de manutenção conseguem agir antes mesmo do chamado do call center ou da percepção pelo centro de controle instalado. Uma economia na operação, em tempo e aumento direto de satisfação pelo cliente.

Esse processo de notificação é disparado com um gerenciador de tarefas automatizado que controla a evolução passo a passo até que a situação seja normalizada. A equipe dispõe de um repositório de documentos online integrado ao sistema para consultas de manuais, plantas, certificações, imagens ou qualquer outro documento que seja importante para a verificação e conclusão da tarefa. Mais uma economia com praticidade, centralização da informação e aumento da eficiência na execução dos serviços de manutenção.

Outro ponto importante na concepção do produto foi o entendimento de que o Bridgemeter não é concorrente dos sistemas SCADA e sim um componente que adiciona flexibilidade e inteligência no monitoramento remoto. O Bridgemeter pode atuar de forma singular ou em conjunto com SCADA já instalados. Na segunda opção resolve ainda diversos problemas de conexão encontrados no mercado, entre eles, a necessidade de conexões múltiplas de CLPs ou múltiplos sistemas SCADA. Mais uma vez, flexibilidade e inteligência aliados para aumento de eficiência.

Como exemplo, utilizando o Bridgemeter a Above-Net integra diversos equipamentos e estações de uma grande companhia de saneamento, permitindo o controle e telemetria remota, além de comunicação confiável com o sistema SCADA do cliente. A Above-Net foi a única capaz de transpor barreiras de fragilidade e deficiência de padronização na comunicação local, entregando uma solução confiável, de alta disponibilidade e excelente custo-benefício.

A Above-Net compreendeu também desde o início, que uma plataforma de IIoT é apenas um dos componentes de um processo de transformação digital e para isso, precisaria interoperar com outros sistemas garantindo a continuidade da informação para conclusão do processo de forma 100% digital. Portanto, o Bridgemeter conta com uma série de opções de comunicação sistemas ERP e de gestão seja por APIs ou outras formas de integração.

Outro fator importante sempre foi a usabilidade. Sistemas tradicionais de monitoramento possuem diversos menu, operação complicada e curva de aprendizado que requer treinamento constante e equipe especializada de programação. A médio e longo prazo, torna-se insustentável pois é uma atividade fora do foco de negócios da empresa que não dispõe de pessoal especializado em programação ou se aventura a criar uma solução por conta própria. Resultado, o processo de mudança é extremamente burocrático e caro.

A interface intuitiva do Bridgemeter oferece configuração dos diagramas de supervisão, dos alarmes e das regras inteligentes de forma instantânea de acordo com a alçada do usuário permitindo atualização imediata nos gatilhos e ações de suporte à decisão. Mais flexibilidade e agilidade para aumento de eficiência.

Finalmente, o Bridgemeter contribui ainda minimizando investimentos, pois é oferecido em pacotes flexíveis como SaaS (solução como serviço) sem custo de desenvolvimento ou aquisição de licenças e pode incluir todos os equipamentos de conectividade, suas atualizações e manutenções.

Tem Interesse em uma Solução de IIoT Inteligente para a sua empresa? Entre em contato conosco hoje mesmo preenchendo o formulário abaixo:

HyTrade Marketing & Vendas B2B

HyTrade Marketing & Vendas B2B